© 2025 Zhangjiagang King Machine Co., Ltd. All rights reserved.Sitemap / Privacy Policy

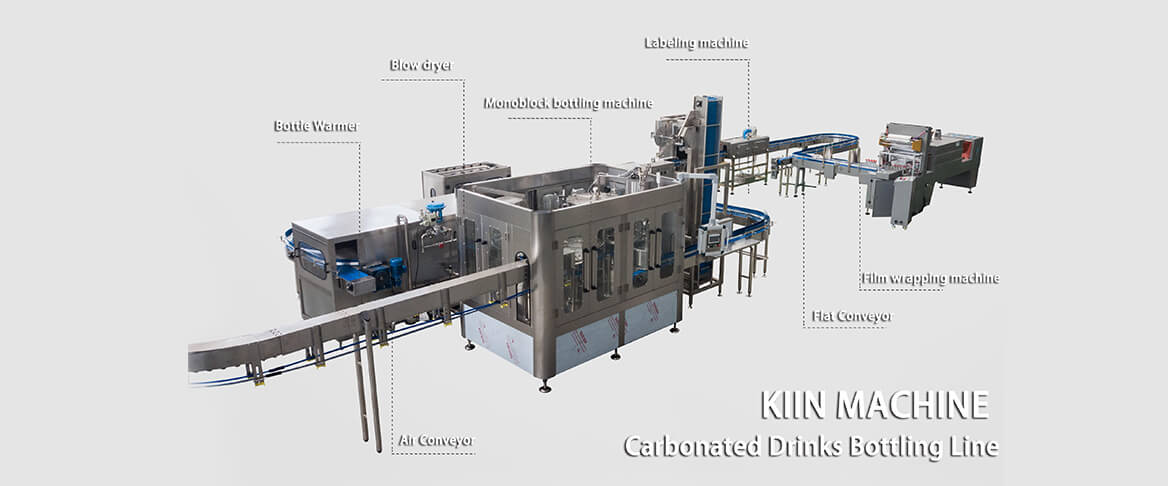

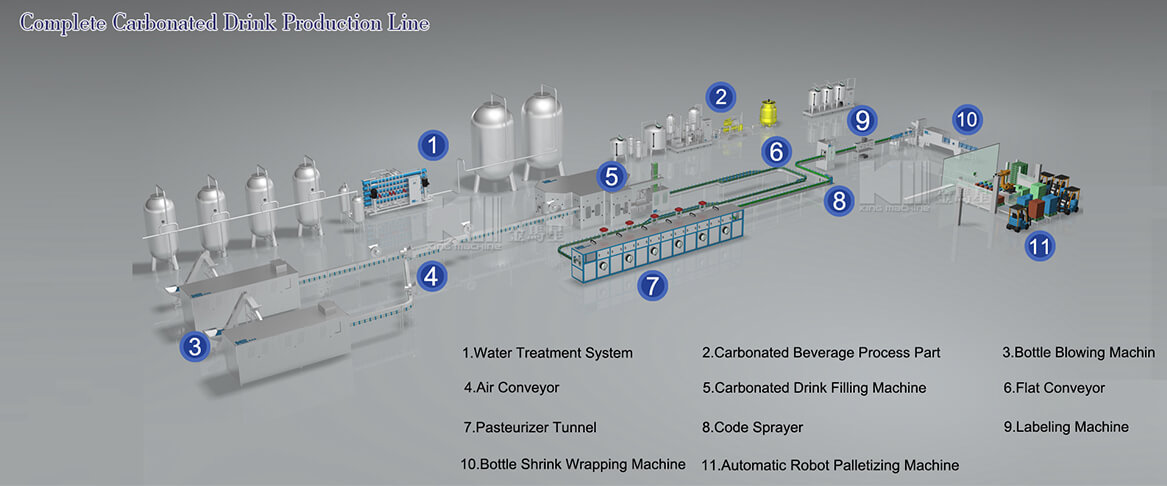

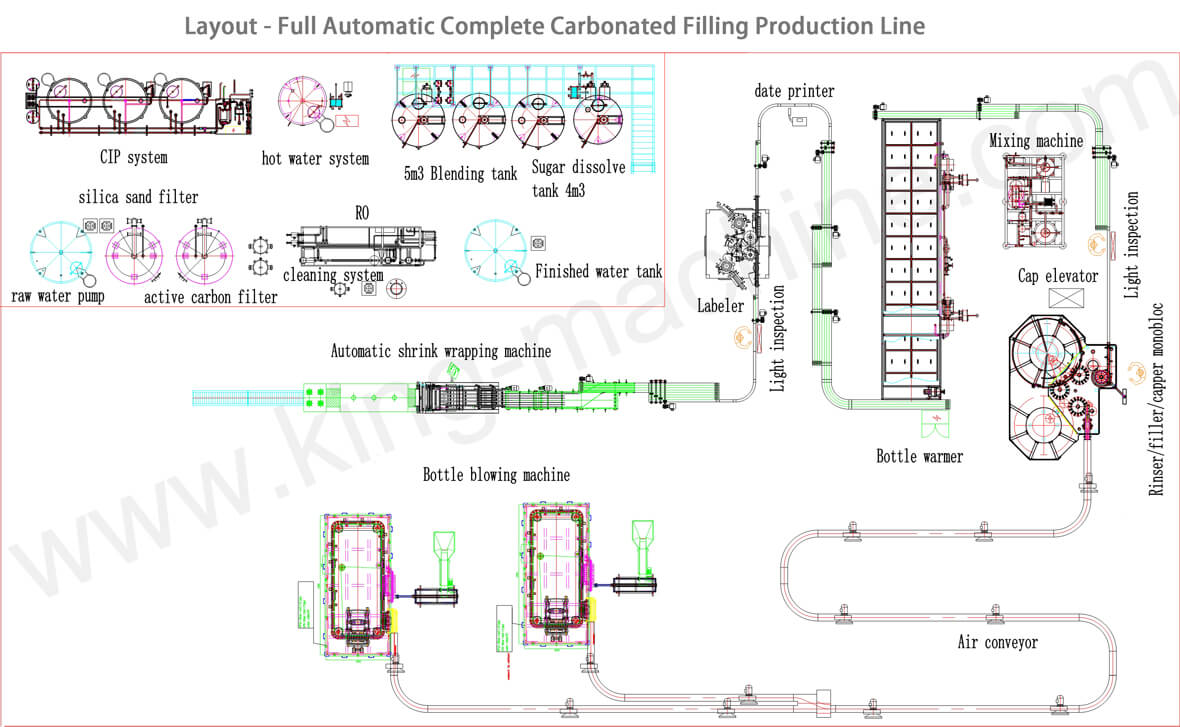

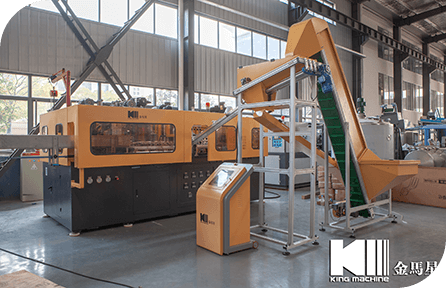

Carbonated Soft Drink Filling Machine

The machine is mainly used for filling carbonated drink. It combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.