© 2025 Zhangjiagang King Machine Co., Ltd. All rights reserved.Sitemap / Privacy Policy

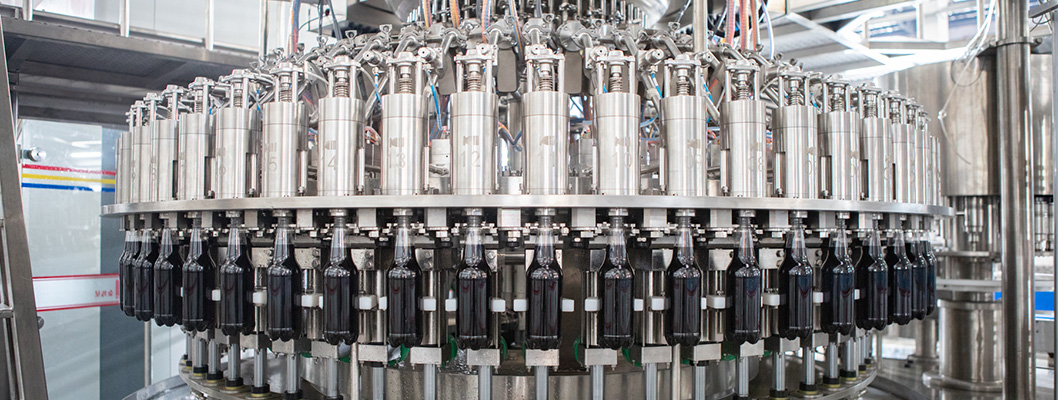

- Technical Innovation

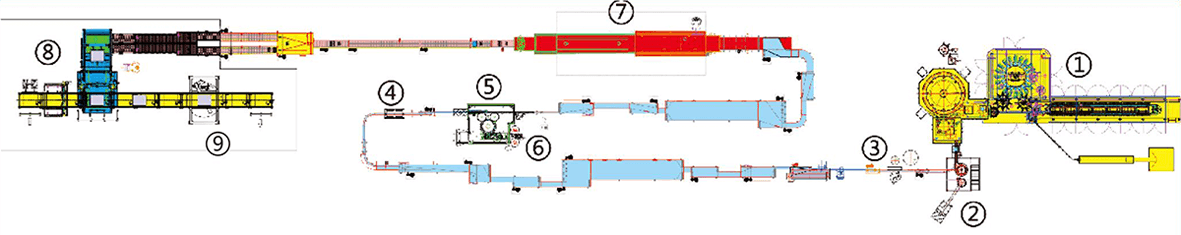

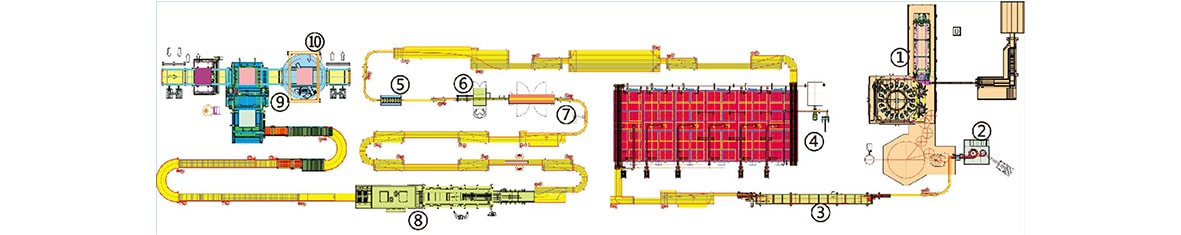

- 1. Optimized cam curve;

- 2. Reduced noise, more stable;

- 3. Energy saving, environment friendly;

- 4. Preform electrostatic dust removal,optimized bottle neck protection;

- 5. Bottle neck camera inspection;

- 6. Preform dumper;

- 7. Cap electrostatic dust removal;

- 8. Servo motor stretching;

- 9. Mechanical bottle mouth sealing.

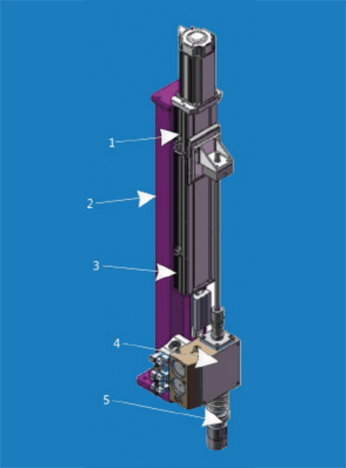

- Technical Innovation

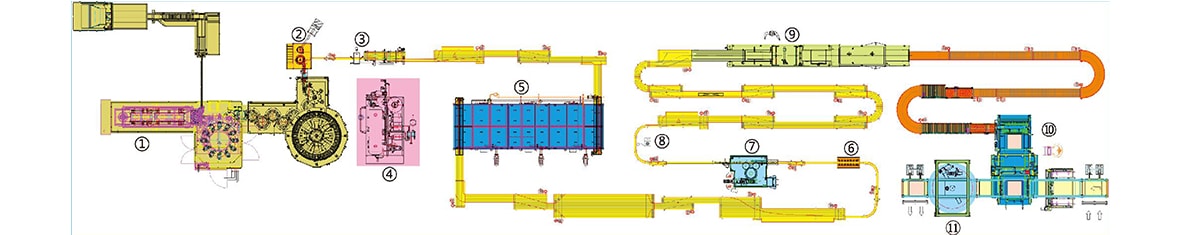

- 1. High revolving speed, and hightorque servo-motor

- 2.Installationbase for electrohydraulic servo cylinder

- 3. Electrohydraulic servo cylinder assembly

- 4. Stretch rod

- 5. Mechanical bottle neck seal & high pressure valve assembly