© 2025 Zhangjiagang King Machine Co., Ltd. All rights reserved.Sitemap / Privacy Policy

Pet Fruit Juice Filling Machine

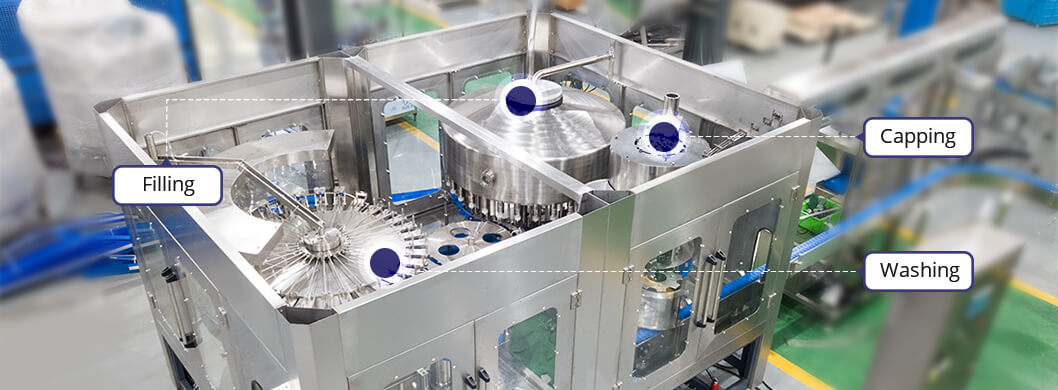

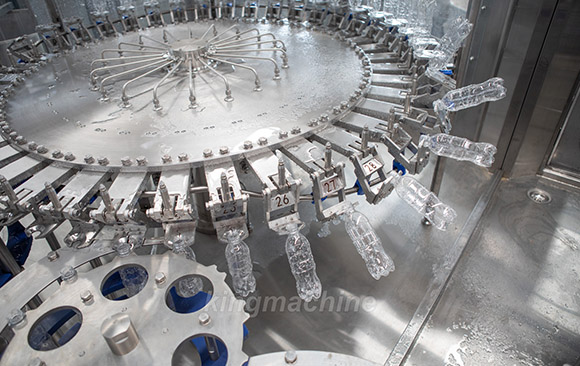

This RCGF Wash-filling-capping 3-in-1unit: The automatic fruit juice packaging machine is used in hot filling and sealing of green tea, black tea, wu-long tea and fruit juice drink, energy drinks, milk drinks, Dairy drinks. This machine integrates washing, filling and capping together. The design is scientific and reasonable. Its appearance is beautiful. Its operation and maintenance is convenient. The automation is high. It is good equipment for choosing hot drink filling machine. Check out our high quality filling machines here.