News

Site Editor

Site

/uploads/image/694e24f48271f.png

This article compares these three valve types and explains why Pulp electronic filling valves are the ideal solution for juice with pulp and other large-particle beverages.

Site

/uploads/image/694e24f48271f.png

This article compares these three valve types and explains why Pulp electronic filling valves are the ideal solution for juice with pulp and other large-particle beverages.

Comparing Filling Valve Technologies: Why Electronic Filling Valves Are Ideal for Juice with Pulp

Views: 706

Author: Site Editor

Publish Time: 2025-07-28

Origin: Site

In the beverage industry, filling accuracy, efficiency, and compatibility with different liquid types—especially those with pulp or particulates—depend heavily on the filling valve technology used. Your choice between mechanical valves, half-electronic valves, and electronic flowmeter valves can significantly affect product quality and production reliability.

This article compares these three valve types and explains why Pulp electronic filling valves are the ideal solution for juice with pulp and other large-particle beverages.

1. Mechanical Valves: Traditional but Limited

Mechanical filling valves are manually operated systems where the open/close mechanism and static (settling) functions are controlled by mechanical buttons. The liquid level is managed via air return pipes.

Disadvantages:

Difficult to control static and exhaust timing → causes bubbling.

Inconsistent fill levels.

Not suitable for pulpy or viscous beverages.

Manual operation results in slower filling and higher labor intensity.

2. Half-Electronic Valves: A Partial Upgrade

Half-electronic valves automate the opening and closing process using a cylinder, while still controlling liquid level via air return. Static and exhaust are handled automatically by the cylinder.

Improvements over mechanical valves:

Better control over static and exhaust time → reduces bubbling.

Longer lifetime due to pneumatic automation.

Faster and more stable than purely mechanical systems.

However, they still rely on basic air-return systems and are not optimal for beverages containing large particles.

3. Flowmeter-Based Electronic Filling Valves: Precision and Versatility

Flowmeter valves represent a full electronic solution. Valve opening/closing and static/exhaust actions are all automated by cylinders, while liquid levels are precisely controlled using flowmeters (e.g., Krohne brand).

Key Advantages:

High filling accuracy with flowmeter-based control.

Fully automated system → reduces operator error.

Excellent control of static time and exhaust to prevent bubbling.

Long operational life and adaptability to different bottle sizes and beverages.

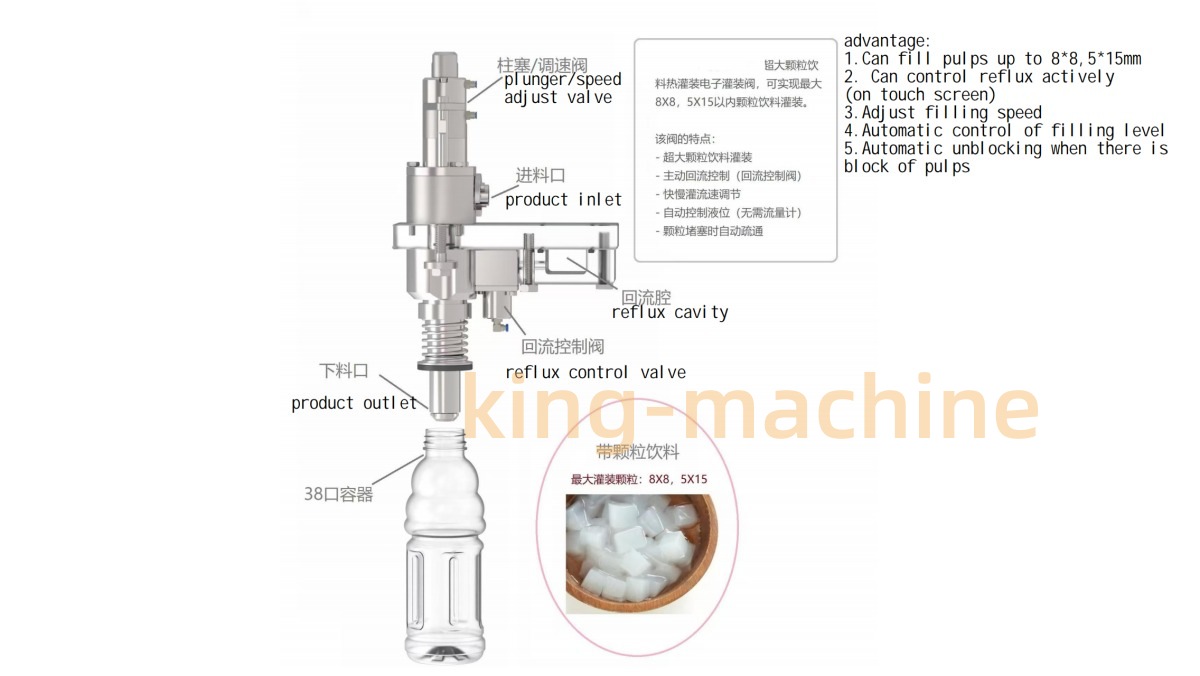

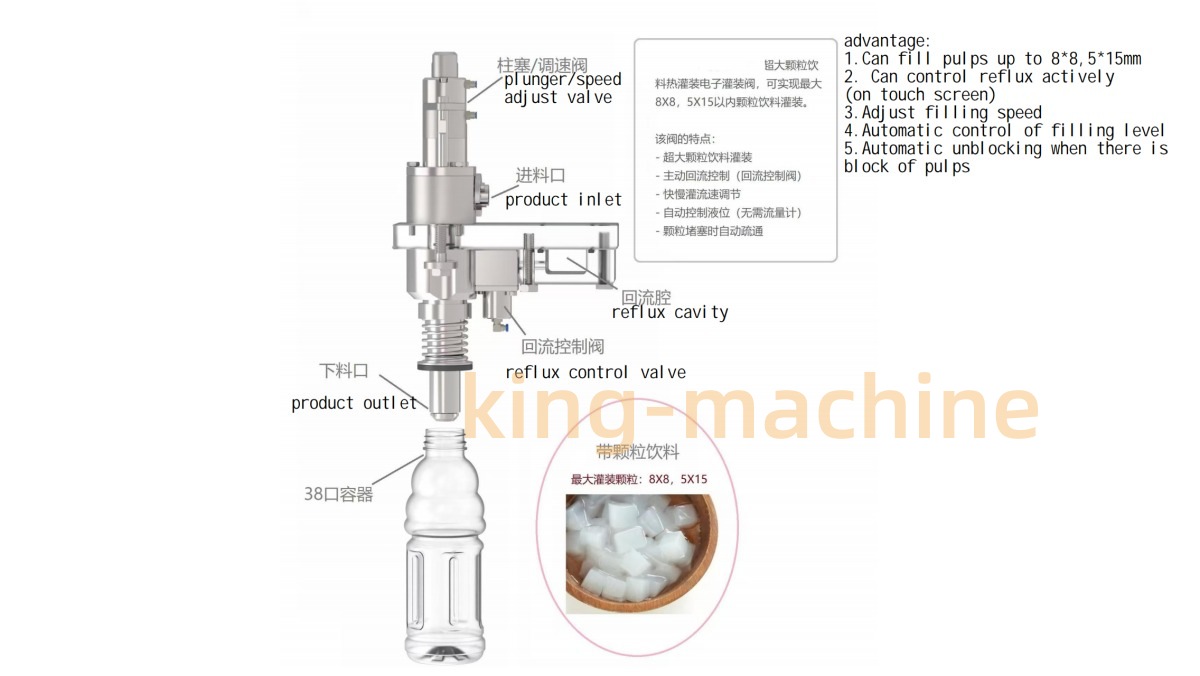

4. Specialized Pulp Electronic Filling Valves: Engineered for Juice with Pulp

For high-viscosity and large-particle beverages such as juice with pulp, standard flowmeter valves may not be sufficient. That’s where Pulp electronic filling valves come into play—offering tailored features for these demanding products.

Advantages of Pulp Electronic Filling Valves:

Handles Large Particles Efficiently

Fills pulps up to 8×8 mm or 5×15 mm without clogging.

Active Reflux Control

Prevents pulp from backing up into the tank—settings are easily adjusted via touchscreen.

Adjustable Filling Speed

Allows fine-tuning based on product thickness and pulp concentration.

Automatic Filling Level Control

Ensures consistent fill levels even with variable flow characteristics.

Self-Unblocking Mechanism

Detects and clears pulp blockages automatically—minimizing downtime.

These features make Pulp electronic filling valves the most advanced solution for juice with pulp and similar beverages that challenge traditional filling systems.

5. Compatibility with Hot Filling Processes

Hot filling valves must tolerate high temperatures while maintaining hygiene and sealing integrity. Electronic filling valves, especially those designed for pulp handling, are well-suited for hot filling thanks to:

Temperature-resistant materials.

Closed-system operation.

Clean-in-place (CIP) compatibility.

Combining pulp-handling capacity with hot filling compatibility offers a significant production advantage.

Conclusion

While mechanical and half-electronic valves may suit basic beverage applications, they fall short for modern, pulp-rich, or viscous drinks. Flowmeter-based electronic filling valves offer accuracy, automation, and stability. But for the ultimate performance, especially in filling juice with pulp, Pulp electronic filling valves provide the best-in-class solution with features like particle handling, reflux control, and auto-unblocking.

King Machine continues to innovate in beverage filling technology, offering advanced electronic filling valves tailored to juice, pulp, and hot filling applications—backed by decades of PET packaging expertise.