News

Site Editor

Site

/uploads/image/694e24f48271f.png

Milk filling machines have high speed, accuracy, and operational stability and are suitable for large-scale production.

By keeping track of these seven components, you can ensure that your milk filling machine is up to date with all the latest features and technology to serve you better.

Site

/uploads/image/694e24f48271f.png

Milk filling machines have high speed, accuracy, and operational stability and are suitable for large-scale production.

By keeping track of these seven components, you can ensure that your milk filling machine is up to date with all the latest features and technology to serve you better.

Components of a Milk Filing Machine

Views: 2546

Author: Site Editor

Publish Time: 2022-10-11

Origin: Site

Milk filling machines are important for all dairy industries, large and small. They are the backbone of your operation, ensuring that the product you provide your customers is always fresh and clean.

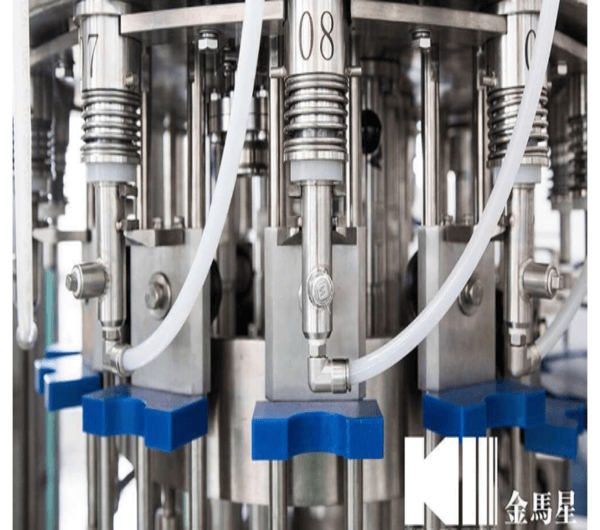

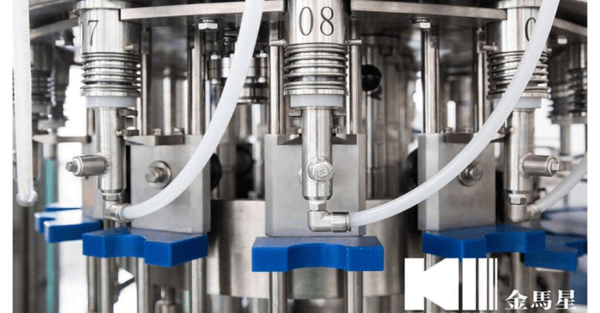

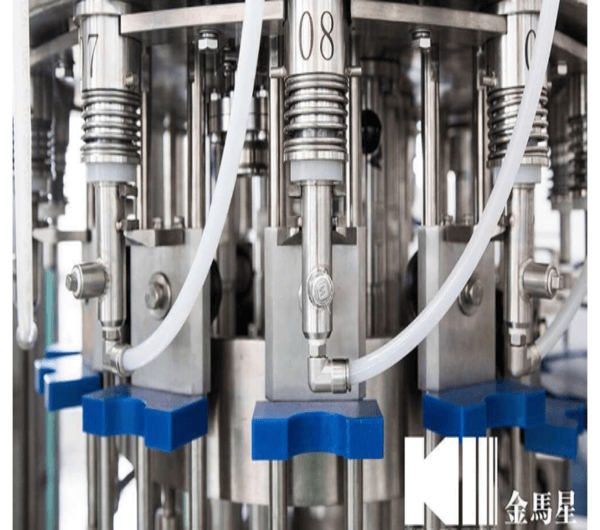

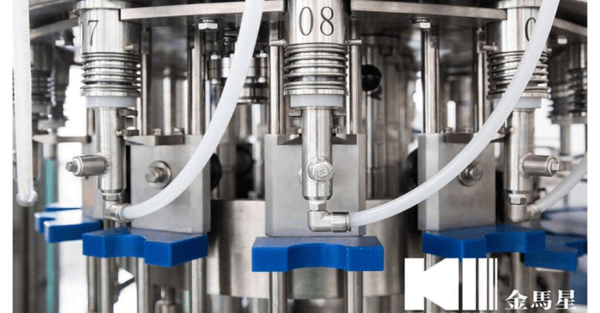

Milk filling machines have high speed, accuracy, and operational stability and are suitable for large-scale production.

By keeping track of these seven components, you can ensure that your milk filling machine is up to date with all the latest features and technology to serve you better.

1. Control Panel

A control panel is the brain of your machine. It's where all of the information from your milk filling machine is displayed and where you can change settings to suit your needs.

The control panel will have indicators for all of the various functions that are happening on your machine, such as filling, pasteurizing and sterilizing, etc.

The status of these functions will be displayed on this screen as well as any error messages that may occur during operation (e.g., "product not inserted").

2. Filler

The filler is the main component of a milk filling machine. It's used to fill the milk in the bottles, which is why it’s so important that you have a good one.

The filler can be adjusted depending on how much liquid you want in each bottle, but this requires some skill and experience because it involves working with delicate parts that require care when manipulating them.

3. Tubular Cleaner

Tubular cleaner, which is made of steel and equipped with a brush to clean the tubes. The tubular cleaner cleans the tubing that feeds into your bottle or carton as well as any other components along its length (such as pumps).

This may include an agitator to remove any particles from within it before entering into your product line.

4. Tube Guard

The tube guard is placed inside the tubes during the filling process. It prevents milk from escaping through gaps between the inner wall of the tube and its outer surface of it.

5. Totalizer

The totalizer measures how much milk has been filled into each component at every point in time. It helps to determine when all components have been filled with milk.

6. Conveyor system

The conveyor system is used to move bottles from one place to another, or move them from one machine to another. It is made up of several components including a belt, drive motors, bearings, etc.

The belt is stretched across the entire width of the machine and passes over pulleys mounted on both sides of it. A motor drives this belt which in turn moves bottles along it with great speed.

7. Capper

The capper is a device used to apply a capping onto a filled bottle. It is designed to apply the cap on top of the bottle, locking it in place and creating an airtight seal with the cork.

A capper can be thought of as a machine that applies pressure around the top of your bottles, causing them to automatically close once they're filled with liquid.

Purchase your milk filling machine from us

Milk filling machines are used to fill milk bottles, cap the milk and clean the bottles. These machines are also used to convey the bottles from a filling station to another point in a plant.

When you're ready to purchase your milk filling machine, we are here to help. We have an excellent team of experts, so our knowledge and expertise are second-to-none.

Our products are high-quality and we offer competitive prices on all of our products and accessories. Kindly click here to place an order.