News

Site Editor

Site

/uploads/image/694e24f48271f.png

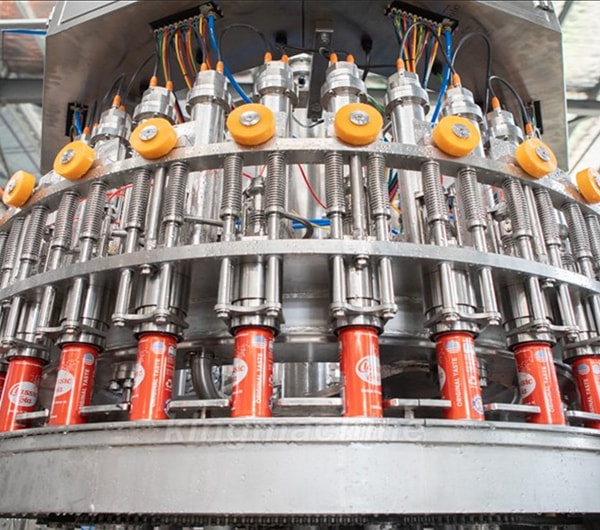

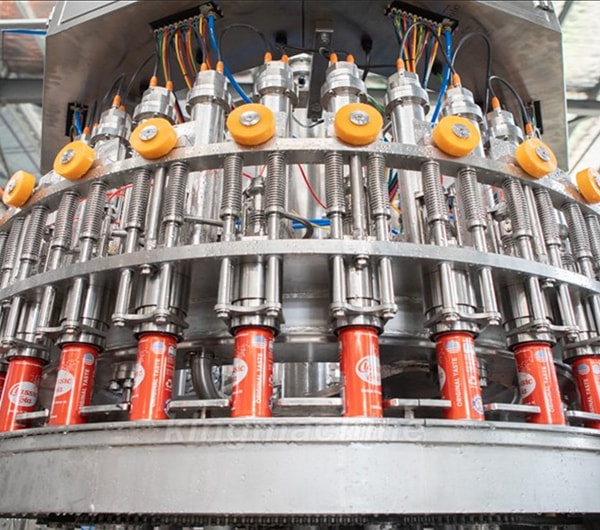

This canning filler uses float-ball cylinder type volumetric filling, the filling is controlled with electronic valve, so that ensure the filling is accurate, difference can be controlled < ±1ml (Actual of single valve ±0.5ml). In additions, the filling volume can be adjusted on line without shutdown the machine.

The machine is equipped with cleaning cups, can do CIP circulation rinsing.

Site

/uploads/image/694e24f48271f.png

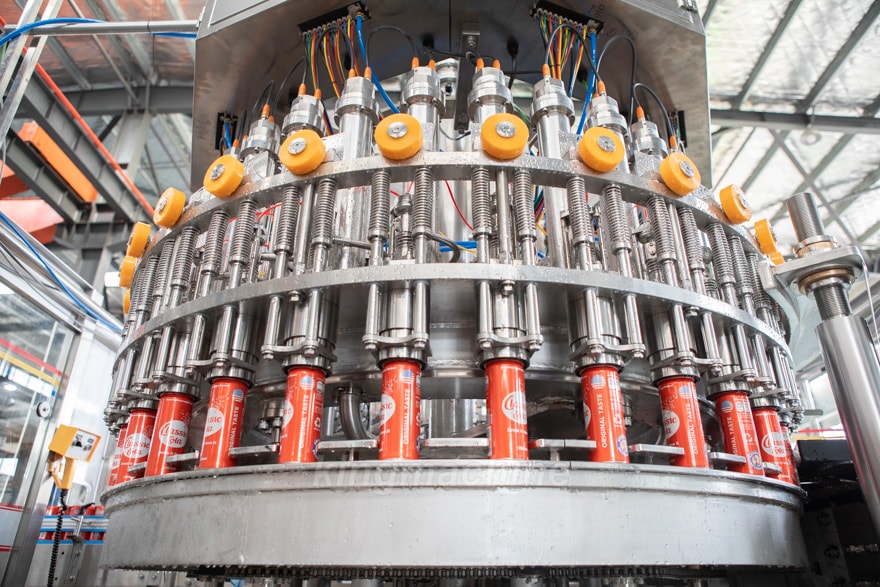

This canning filler uses float-ball cylinder type volumetric filling, the filling is controlled with electronic valve, so that ensure the filling is accurate, difference can be controlled < ±1ml (Actual of single valve ±0.5ml). In additions, the filling volume can be adjusted on line without shutdown the machine.

The machine is equipped with cleaning cups, can do CIP circulation rinsing.

Flowmeter Type Can Filler/Seamer for CSD

Views: 2894

Author: Site Editor

Publish Time: 2022-01-25

Origin: Site