When it comes to bottled water production, one of the most critical decisions a manufacturer must make is the choice of packaging material—glass or plastic. This choice not only impacts consumer perception but also dictates the design, cost, and efficiency of the entire water filling line.

Glass bottle water filling lines and plastic bottle water filling lines operate differently because of the inherent properties of their containers. Glass is heavier, fragile, and premium, while plastic is lightweight, versatile, and widely used in mass production. Each option carries unique advantages and challenges.

In this article, we’ll compare glass and plastic bottle water filling lines step by step, exploring their pros and cons to help you decide which solution aligns with your production goals.

What is Glass Bottle Water Filling Lines

Glass bottle water filling lines are designed to handle fragile and heavy containers with precision. Because glass bottles are prone to breakage, the filling line must incorporate special adjustments and safety measures.

Key Features

Heavier conveyors and handling systems to support bottle weight.

Gentle rinsing and sterilization to maintain hygiene without risking cracks.

Lower production speed compared to plastic lines due to fragility.

Compatibility with returnable bottles in some regions, allowing bottles to be sterilized and reused.

Applications

Glass bottles are often preferred by:

Premium bottled water brands.

Luxury hotels and restaurants.

Markets where sustainability and recyclability are strong selling points.

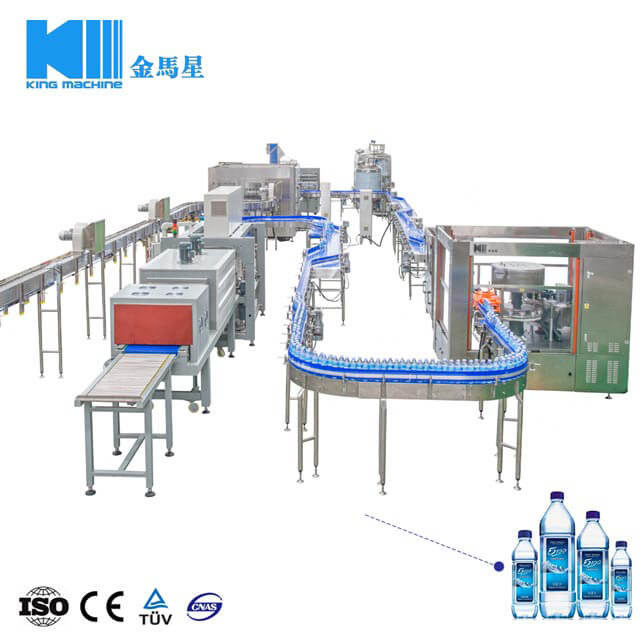

What is Plastic Bottle Water Filling Lines

Plastic bottle water filling lines are the most common in the bottled water industry, especially for PET bottles. These lines are typically integrated with bottle blowing machines, allowing manufacturers to produce bottles on-site from preforms.

Key Features

Lightweight container handling, enabling high-speed filling.

Integrated PET blowing system for cost and space efficiency.

Versatility in bottle shapes and sizes, making it easy to create branded packaging.

Lower equipment cost compared to glass filling lines.

Applications

Plastic bottles are widely used by:

Mass-market water producers.

Large-scale manufacturing plants.

Brands aiming for affordability and accessibility.

Pros and Cons of Glass Bottle Water Filling Lines

Pros of Glass Bottle Water Filling Lines

Premium Look and Feel

Glass bottles convey luxury and quality. For brands targeting the high-end market, glass offers a strong competitive advantage.

100% Recyclable and Reusable

Glass can be endlessly recycled without losing quality. In some markets, refillable glass bottles are collected, sterilized, and reused.

Better Barrier Properties

Glass provides an excellent barrier against oxygen and contaminants. Unlike plastic, it does not leach chemicals into the water.

Eco-Friendly Perception

With growing concerns about plastic waste, glass bottles appeal to eco-conscious consumers.

Cons of Glass Bottle Water Filling Lines

Higher Cost

Glass bottles are more expensive to produce, and the filling line itself requires sturdier, specialized equipment.

Heavier to Transport

The added weight increases logistics and shipping costs significantly.

Slower Production Speeds

Because bottles must be handled gently, glass filling lines operate slower than their plastic counterparts.

Risk of Breakage

Glass bottles can break during handling, filling, or shipping, leading to product loss and safety concerns.

Pros and Cons of Plastic Bottle Water Filling Lines

Pros of Plastic Bottle Water Filling Lines

Lightweight and Cost-Efficient

Plastic bottles are much cheaper to manufacture and transport, making them the go-to choice for mass-market water production.

High-Speed Production

Plastic filling lines can operate at very high speeds, sometimes exceeding tens of thousands of bottles per hour.

Design Flexibility

PET technology allows bottles to be molded into various shapes and sizes, helping brands stand out on the shelf.

Lower Equipment Investment

Plastic filling lines are generally less expensive than glass lines and easier to maintain.

Cons of Plastic Bottle Water Filling Lines

Environmental Concerns

Plastic waste is a global issue, and many regions are tightening regulations on single-use plastics.

Shorter Shelf Life

Compared to glass, plastic has weaker barrier properties, which may affect water taste and freshness over long storage periods.

Potential for Chemical Leaching

Poor-quality plastics can leach substances into the water if exposed to heat or sunlight.

Regulatory Challenges

Some markets impose taxes or restrictions on plastic packaging, which may increase costs.

Key Factors to Consider When Choosing Between Glass and Plastic Filling Lines

1. Target Market

If you’re aiming at the luxury or eco-conscious consumer, glass bottles may reinforce your brand image.

If your focus is the mass market, plastic bottles remain the practical choice due to affordability and availability.

2. Production Scale and Speed

Glass bottle lines are better suited for smaller-scale premium production.

Plastic bottle lines excel in large-scale, high-speed operations.

3. Budget and Operational Costs

Glass lines require higher investment in both equipment and logistics.

Plastic lines are more cost-efficient upfront and operationally.

4. Sustainability Goals

Glass is favored where sustainability and recyclability are key priorities.

Plastic lines can still be eco-friendly if paired with rPET (recycled PET) solutions.

5. Brand Image and Positioning

Glass communicates prestige, purity, and environmental responsibility.

Plastic communicates affordability, accessibility, and practicality.

Comparison Table: Glass vs. Plastic Water Filling Lines

Factor | Glass Bottle Filling Line | Plastic Bottle Filling Line |

Cost of Bottles | High | Low |

Equipment Cost | Higher (requires heavy-duty machinery) | Lower |

Production Speed | Moderate to Low | High (thousands of bottles/hour) |

Durability | Fragile (breakable) | Durable and flexible |

Transport Costs | Higher (heavier weight) | Lower (lightweight bottles) |

Sustainability | 100% recyclable, eco-friendly perception | Recyclable but faces environmental scrutiny |

Market Positioning | Premium, luxury, eco-conscious brands | Mass market, cost-sensitive brands |

Conclusion

Both glass bottle and plastic bottle water filling lines play vital roles in the bottled water industry, but they serve different market needs.

Glass offers a premium, sustainable, and eco-friendly image, but comes with higher costs, slower production, and fragile handling.

Plastic provides cost-effectiveness, speed, and versatility, but faces increasing environmental challenges and a shorter shelf life.

The right choice depends on your target audience, production capacity, budget, and long-term sustainability strategy.

For manufacturers seeking reliable, customizable, and efficient solutions for either glass or plastic filling lines, King Machine offers advanced technologies designed to meet diverse production needs. With years of expertise and a strong reputation in the beverage machinery industry, King Machine ensures that your filling line investment delivers efficiency, quality, and long-term value.