News

Site Editor

Site

/uploads/image/694e24f48271f.png

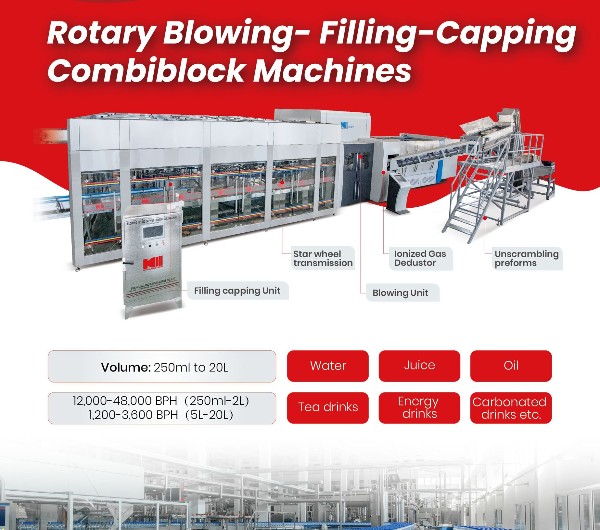

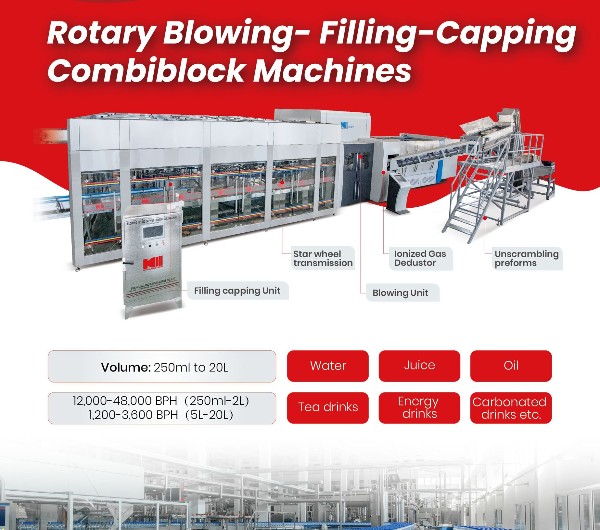

Investing in a high-quality blowing, filling, capping, and combiblock machine can significantly increase efficiency in the bottling process.

Site

/uploads/image/694e24f48271f.png

Investing in a high-quality blowing, filling, capping, and combiblock machine can significantly increase efficiency in the bottling process.

The Benefits of Investing in a High-Quality Blowing, Filling, Capping, and Combiblock Machine

Views: 1907

Author: Site Editor

Publish Time: 2023-04-11

Origin: Site

Are you looking for a way to increase your production efficiency and reduce labor costs in the bottling process? Look no further than investing in a high-quality blowing, filling, capping, and combiblock machine. These machines streamline the bottling process and provide numerous benefits to companies involved in the production of bottled beverages. In this blog post, we'll explore the advantages of investing in this equipment and why it's a smart decision for your business.

Increased Efficiency:

Investing in a high-quality blowing, filling, capping, and combiblock machine can significantly increase efficiency in the bottling process. These machines are designed to streamline the process, reducing labor costs and increasing productivity. They can also produce bottles at a faster rate than traditional methods, allowing you to meet demand more quickly. With increased efficiency, you can produce more products in less time, ultimately boosting your bottom line.

Reduced Noise and Improved Stability:

High-quality blowing, filling, capping, and combiblock machines are designed with noise reduction and stability in mind. They often have features such as vibration control and soundproofing to reduce noise levels in the production environment, creating a safer and more comfortable workspace. Additionally, these machines are engineered to operate smoothly and efficiently, improving their overall stability and reliability.

Sustainable Manufacturing:

Sustainability is becoming an increasingly important consideration in the manufacturing industry, and investing in a high-quality blowing, filling, capping, and combiblock machine can help you achieve sustainable manufacturing goals. These machines often use less energy and produce less waste than traditional bottling equipment, making them a more environmentally friendly option. By choosing sustainable manufacturing practices, you can reduce your carbon footprint and appeal to consumers who want to support eco-friendly products.

Ensuring Quality Control:

Maintaining consistent quality control is crucial in the beverage industry. A high-quality blowing, filling, capping, and combiblock machine can help ensure that your bottles are filled accurately and consistently, reducing the risk of product defects and recalls. These machines often include features such as automatic weight control and pressure regulation to maintain precise filling levels, ensuring that every bottle meets your quality standards.

Improved Stretching Accuracy:

The stretching process is a critical step in the bottling process, and accuracy is essential to producing high-quality bottles. A high-quality blowing, filling, capping, and combiblock machine can improve stretching accuracy by providing precise control over the stretching process. This results in more consistent bottle shapes and sizes, reducing waste and improving product quality.

In conclusion

Investing in a high-quality blowing, filling, capping, and combiblock machine is a smart decision for companies involved in the production of bottled beverages. These machines offer numerous benefits, including increased efficiency, reduced noise and improved stability, sustainable manufacturing, ensuring quality control, and improved stretching accuracy. By choosing the right machine for your business, you can streamline your bottling process and improve your bottom line while also reducing your carbon footprint.

If you're interested in learning more about the benefits of investing in a high-quality blowing, filling, capping, and combiblock machine, or if you're ready to take the next step and purchase one for your business, please contact us today. Our expert team can help you find the perfect machine to meet your specific needs and boost your production efficiency. Don't wait – invest in the future of your business today!