News

Site Editor

Site

/uploads/image/694e24f48271f.png

Site

/uploads/image/694e24f48271f.png

Zip-top cans represent the future.

Views: 1726

Author: Site Editor

Publish Time: 2021-12-06

Origin: Site

New production lines have changed everything.

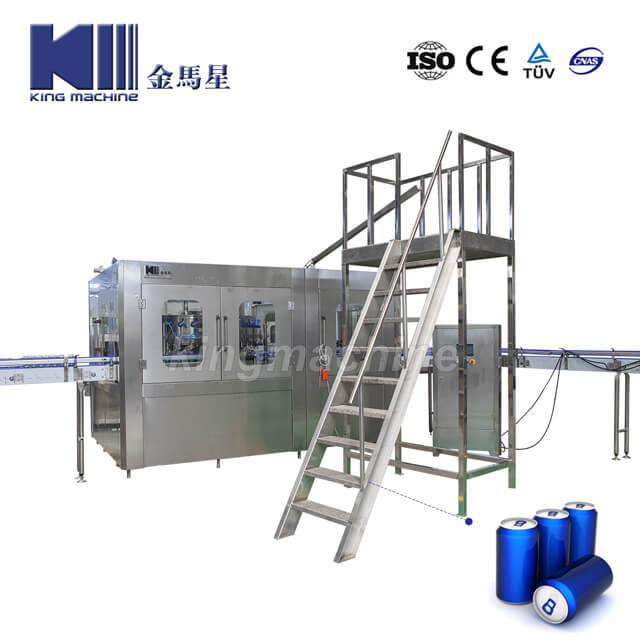

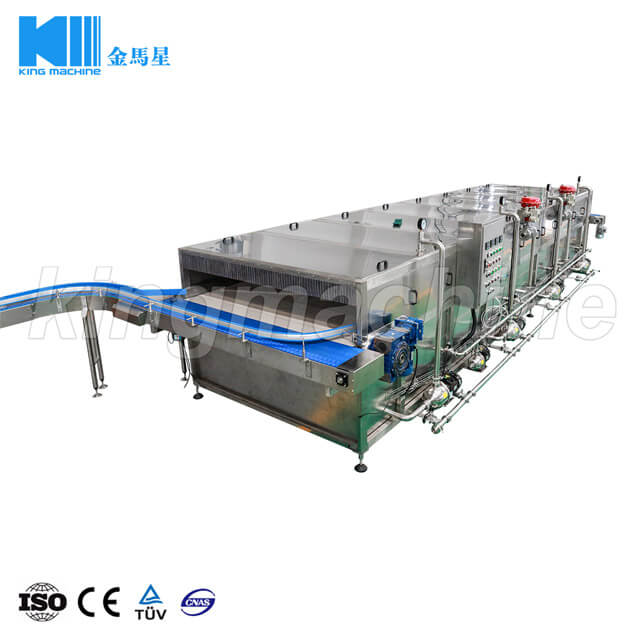

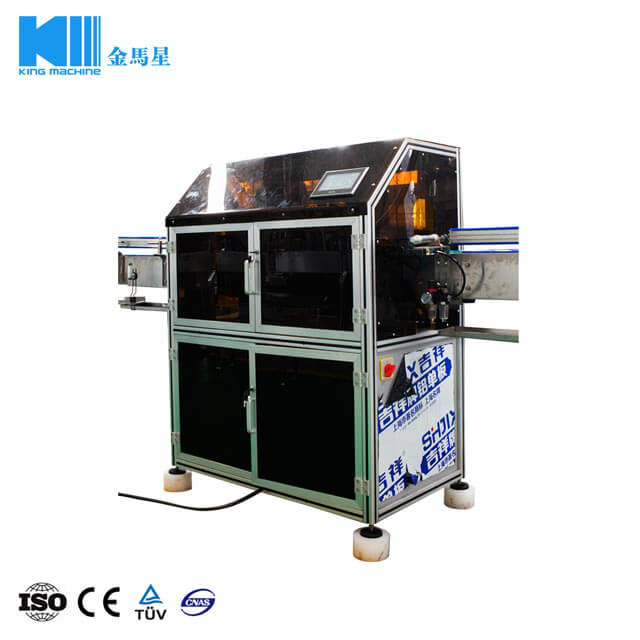

Carbonated Drinks Bottling lines for cans, Now let's start to understand the new pop can beverage filling machine.

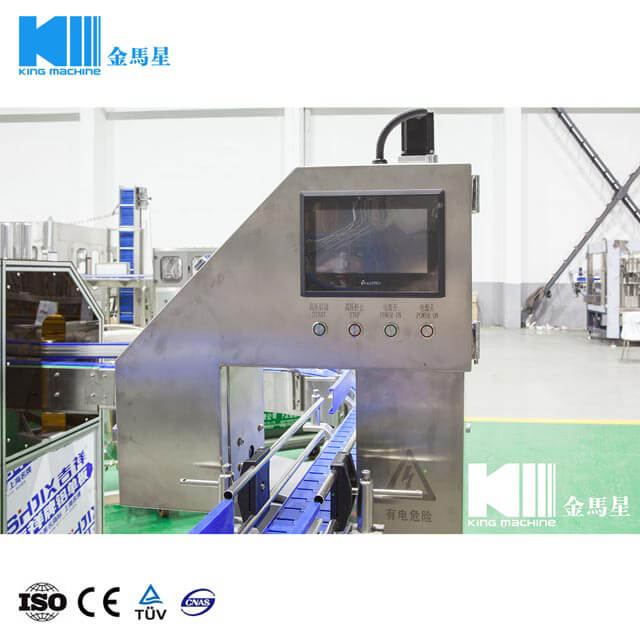

The method of operation of the new filling valve

The can is fed into the filler and positioned underneath the filling valve. The valve is pneumatically lowered onto the can for pressing-on. Thanks to a differential pressure chamber, the cans are also centred and pressed onto the valve with

extreme care. The filling process begins immediately after rinsing. An inductive flow meter checks the quantity of inflowing liquid. The valve closes once the specified filling volume has been

32 head filling valve and 6-head capping machine,High speed production up to 15000cph for 250ml Aluminum can,This can filling machine for carbonated soft drinks is about to be shipped to Guinea on the west coast of West Africa.

If you also need soft drink can filling machine, carbonated drinks can filling machine, CSD can filling machine, fruit juice can filling machine and beer can filling machine, please contact us, We will confirm more details with you as soon as possible to offer customized solution for you .