News

Site Editor

Site

/uploads/image/694e24f48271f.png

The stable output is 5000 cans per hour, 8000 cans per hour and 12000 cans per hour respectively. The filling method adopts beer filling technology. This kind of filling valve solves the problem of filling bubbles and effectively solves the problem of liquid level deviation in the production process, The accuracy of filling and the working efficiency of the whole production line are improved.

Site

/uploads/image/694e24f48271f.png

The stable output is 5000 cans per hour, 8000 cans per hour and 12000 cans per hour respectively. The filling method adopts beer filling technology. This kind of filling valve solves the problem of filling bubbles and effectively solves the problem of liquid level deviation in the production process, The accuracy of filling and the working efficiency of the whole production line are improved.

Brief Introduction Of King-Machine CSD Drink Can Filling Machine Series

Views: 2723

Author: Site Editor

Publish Time: 2022-03-04

Origin: Site

For can filling machine ,King machine company provides models with different output, from 2000-3000 cans per hour, 5000-8000 cans per hour, 15000 cans per hour, 20000 cans per hour, to 36000 cans per hour and so on. According to the different output, filling method is also different.

According to the types of filling valves, we roughly divide the filler into three generations.

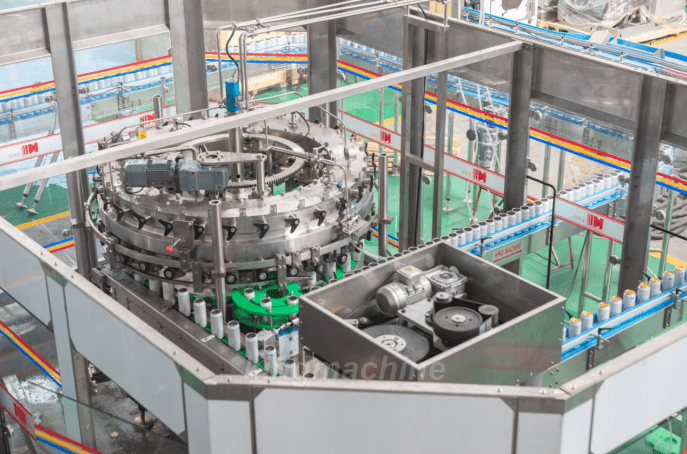

1. First is the traditional pop can filling machine with aerated beverage filling valve. The number of filling valve heads is 12 and 18, and the production capacity is 2000 cans per hour and 5000 cans per hour respectively. This model is characterized by compact structure, strong practicability and high cost performance, because it belongs to our mature product and many users are currently in use, It is an ideal choice for many customers who are just beginning to make beverage production.

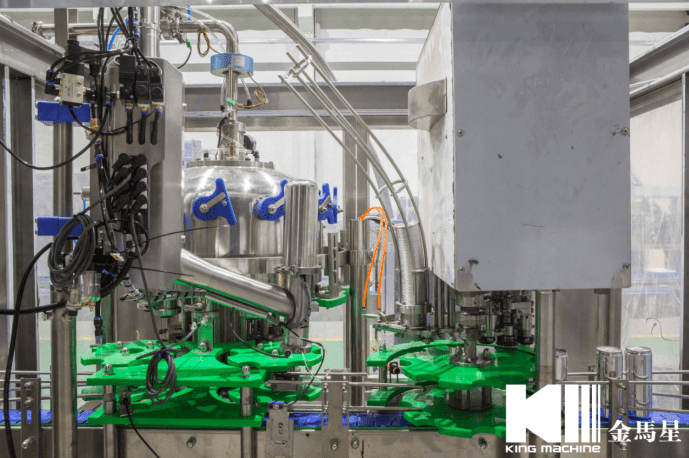

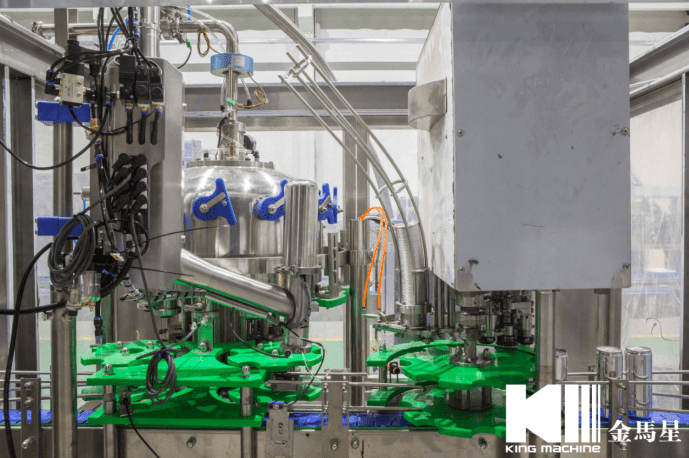

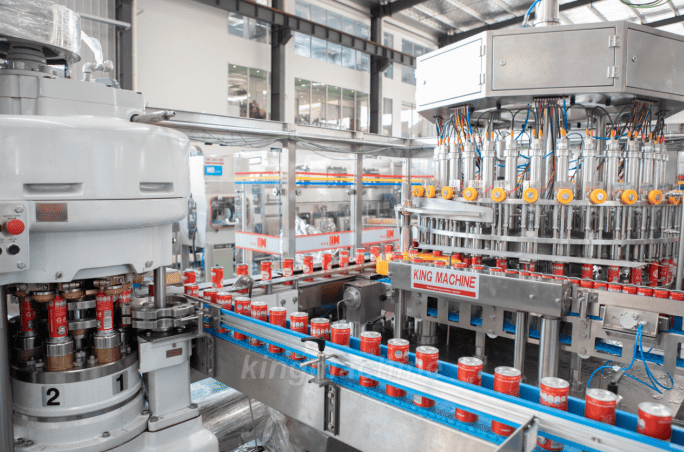

2. The second can filling machine with 18 cans, 24 cans and 32 cans. The stable output is 5000 cans per hour, 8000 cans per hour and 12000 cans per hour respectively. The filling method adopts beer filling technology. This kind of filling valve solves the problem of filling bubbles and effectively solves the problem of liquid level deviation in the production process, The accuracy of filling and the working efficiency of the whole production line are improved.

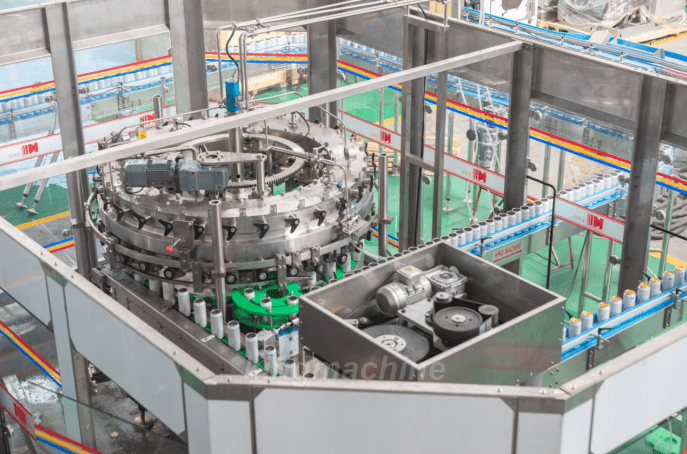

3. The third generation of king machine can filling machine. It is characterized by compact structure and very convenient maintenance and operation. However, the remarkable feature is that the filling machine is equipped with floating ball measuring cylinder electronic pneumatic valve. It is the most first-class technology for gas filling of cans in the world. It adopts floating ball measuring cylinder fixed volume filling. The filling process is controlled by electronic valve and the filling capacity is constant.

| 1st Generation Can filler | 2nd Generation Can filler | 3rd Generation Can filler |

Filling Head | 12heads 18heads | 12heads 18heads 32heads | 12heads 18heads 32heads 40heads 54heads etc |

Capacity | 2000cans/h-5000cans/h | 5000cans/h-12000cans/h | 8000cans/h- 30000cans/h |

Filling Type | Isobaric filling | Isobaric filling beer type | Floating ball volumetric type |

Structure | Integral cleaning table Easy to clean All stainless steel | Integral cleaning table Easy to clean All stainless steel | Integral cleaning table Easy to clean easy Operation and maintenance |

Machine Advantage | High cost performance, low output suitable for customers who have just entered beverage area | Compact, stable foam free filling with high yield. Beer filling valve has stable performance and high cost performance. | High degree of humanization Beautiful atmosphere Online remote assistance The filling capacity can be adjusted online without shutdown, which can be adjusted as a whole or by a single valve High filling accuracy Filling steps can be set |

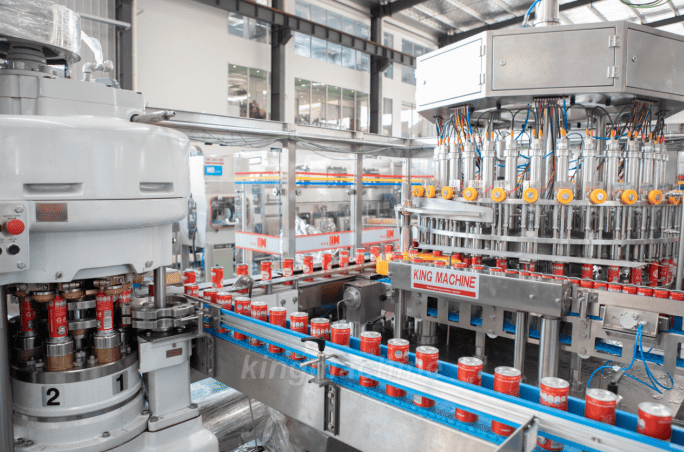

Our beverage filling machine has sold to many customers all around the world as below.

The first generation: has sold to Uzbekistan, USA, Liberia beverage filling manufacture

The Second generation: have sold to Poland, Syria, Nepal ,India CSD DRINK FACTORY Etc.

The third generation: Guinea Israel food and beverage factory etc

When the can enters the can filling machine and is positioned below the can. When pressing, the filling valve is pneumatically pressed on the can. With the help of the pressure chamber, the can is very flexible in the alignment and compression of the filling valve. Low carbon dioxide consumption purging is completed through an independent sanitary group channel, and the filling process is carried out. The electronic floating ball measuring cylinder is used to control the amount of liquid flowing in. The filling accuracy can reach ± 1.0m, which is closed when the set filling capacity is reached. Using an independent pressure relief channel, the pressure at the top of the can is reduced to the ambient pressure again, and then the filling valve is raised from the can through pneumatic control.

Purchase premium can filling machine from King-Machine

King Machine as one of the leading, beverage-packing machine manufacturers has provided quality equipment and amazing service to many of our customers worldwide.If you are looking fo r can filling machine for your plant, we will absolutely be your best choice. Please contact us for more information.