News

Site Editor

Site

/uploads/image/694e24f48271f.png

Procuring an oil filling machine, and how to make it convey desired paybacks to the enterprise has been a hard nut to crack by the stakeholder in the industry.

Site

/uploads/image/694e24f48271f.png

Procuring an oil filling machine, and how to make it convey desired paybacks to the enterprise has been a hard nut to crack by the stakeholder in the industry.

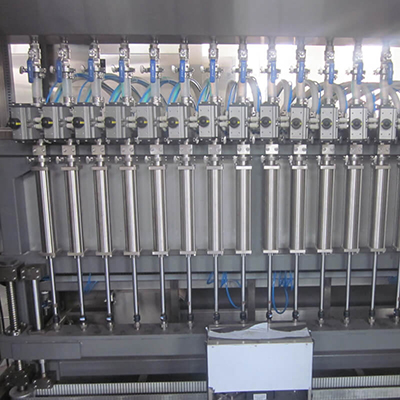

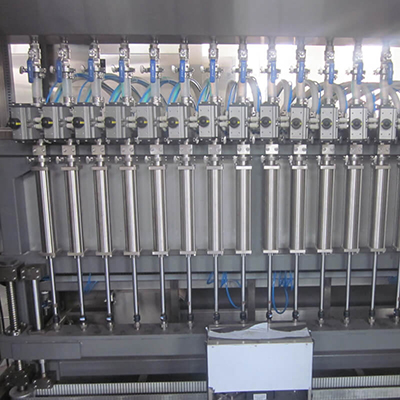

Guidelines To Consider When Investing In Oil Filling Machine

Views: 1950

Author: Site Editor

Publish Time: 2021-01-19

Origin: Site

Procuring an oil filling machine, and how to make it convey desired paybacks to the enterprise has been a hard nut to crack by the stakeholder in the industry.

This headache can be overcome by you sourcing for the right filling machine, either automatic or semi-automatic, which can offer many gains to your enterprise. Some of these gains that come with you following the right guideline for purchasing a filling machine include;

i. Achieving a higher degree of refinement with which the filling operation is performed, which created less or no human filling errors prospect.

ii. It increases the consistency of filling

iii. It reduces product wastage cost

iv. More containers can be filled within a very limited time

Procuring the precise filling machine for your oils is consequently, crucial for guaranteeing that your procedures are adjusted in a suitable, and lucrative manner.

If your oil filling production line needs an upgrade, you need to contact a reliable manufacturer of oil filling machine for your best deal.

Below are some guideline for considerations when procuring your filling machine for oil, and there are not limited to the one mention here alone.

1. Flexibility, and Development Perspective

The flexibility and development perspective is an essential point to consider when buying a filling machine. And this is achieved by consulting a reliable manufacturer to design a flexible benchtop filler. What this means is that this allows the operators to take it away at any phase, and used it as a standalone as well as semi-automatic filler.

The vigor of the benchtop filler system provides improved manufacturing flexibility and safe other purposes in the production line.

2. Precision

Carefully go through the manufacturer's manual to be sure of the precision of the machine. Because the precision in oil filling reduces the cost associated with product wastage, and also allows uniformity during filling. It will be better to work with a reliable supplier that'll offer you diverse filling options to suit your specifications.

For instance, volumetric filling setups fill containers with an accurate volume of your oil product, irrespective of what you may see at the final filling level.

3. Easy to Clean, switch, and strip-down

This is another important point to consider when purchasing your machine. The cleaning feature of your filler is a direct function of tri-clover hopper fittings, grease-free pneumatics, and a speedy belt design. Also, flexible benchtop filler enables easy cleaning, and switch.

4. Sterility

It is important to buy a refabricate product that is in-cooperated to meet the industrial hygienic specification that will ensure contamination-free product.

5. Sustainability

This is one of the essential decisions for selecting your machine because a sustainable supply chain can add to the product selling point of your enterprise.

Get a Durable Oil Filling Machine from us

We are a qualified filling machine manufacturer, such as an oil filling machine with hygienic, and high-quality products for oil packaging.

If you’re preparing to optimize your oil filing production line, we are here to assist you to purchase an automated filling plant. Kindly click here to send us a message or send your order now, and you will not regret contacting us.