As global demand for packaged beverages continues to rise, juice manufacturers face a critical decision when setting up or upgrading production lines: should they invest in a hot juice filling machine or an aseptic juice filling machine?

Both technologies are widely used in the beverage industry, yet they differ significantly in structure, working principle, investment cost, and application scope. Choosing the right system directly impacts product shelf life, packaging design, production efficiency, and overall return on investment.

This article provides a comprehensive comparison to help beverage producers understand the key differences and determine which solution best fits their business strategy.

What Is a Hot Juice Filling Machine?

A hot juice filling machine is designed to fill juice into bottles at elevated temperatures, typically between 85°C and 95°C. The high temperature sterilizes both the beverage and the interior of the container, ensuring microbial safety without requiring a fully sterile filling environment.

Working Principle of a Hot Juice Filling Machine

The process follows several steps:

Product Heating

The juice is heated to sterilization temperature using a pasteurization or heat exchange system.

High-Temperature Filling

The hot liquid is filled into the bottle using a gravity or micro-pressure filling system.

Bottle Inversion (Optional)

After capping, bottles may be inverted briefly to sterilize the cap interior.

Cooling Process

Bottles pass through a cooling tunnel to gradually reduce temperature and prevent deformation.

This process makes the hot juice filling machine particularly suitable for acidic beverages.

Typical Applications

Hot filling is ideal for:

Mango juice filling machine production lines

Litchi juice filling machine applications

Citrus juice

Tea beverages

High-acid fruit drinks (pH < 4.5)

Key Features

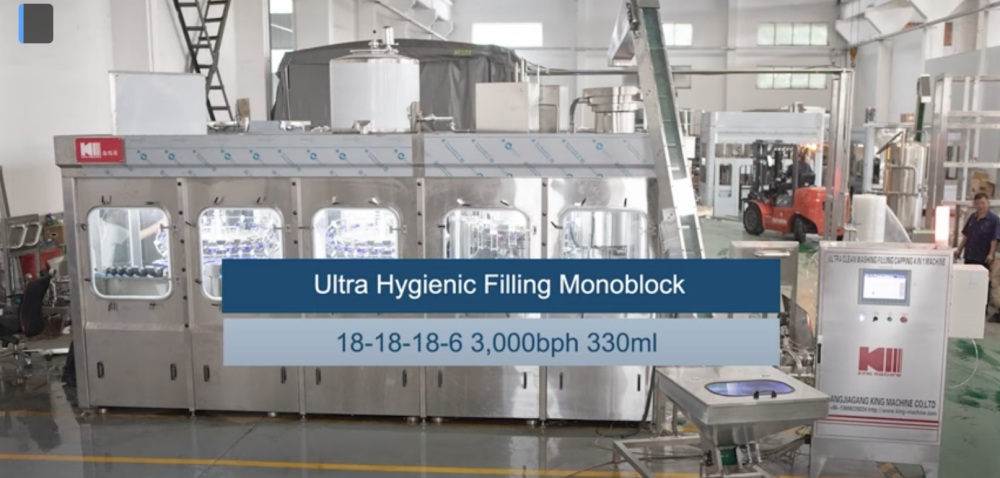

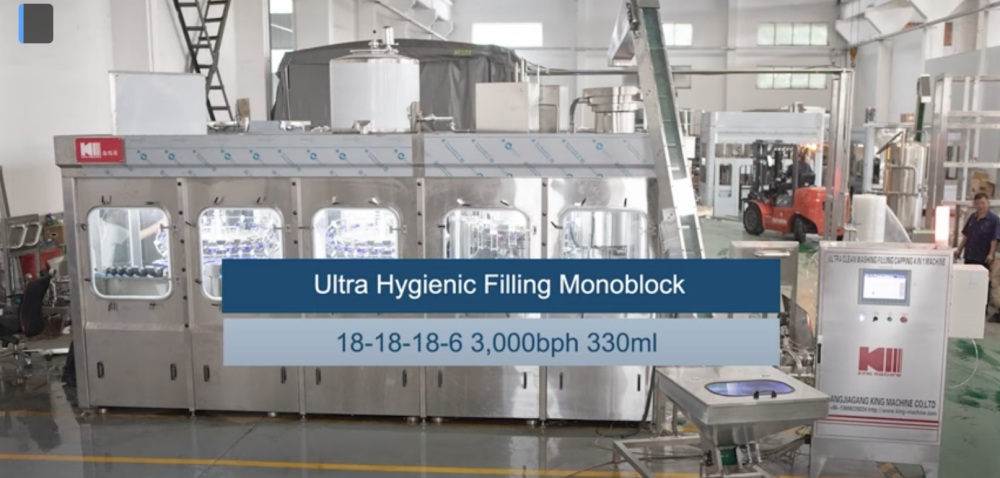

Often configured as a 3-in-1 monoblock (rinsing–filling–capping)

Heat-resistant PET bottle compatibility

Relatively simple mechanical structure

Mature and stable technology

For many manufacturers, a bottle juice filling machine using hot filling technology offers a cost-effective and reliable solution.

What Is an Aseptic Juice Filling Machine?

An aseptic juice filling machine operates under sterile conditions, allowing beverages to be filled at ambient temperature while maintaining commercial sterility.

Unlike hot filling, aseptic filling separates sterilization of the product and packaging from the filling process.

Working Principle of an Aseptic Juice Filling Machine

The aseptic process includes:

UHT Sterilization of Product

Juice is sterilized using Ultra High Temperature (UHT) treatment.

Bottle and Cap Sterilization

Bottles and caps are sterilized using hydrogen peroxide or other sterilizing agents.

Sterile Environment Filling

Filling occurs in an enclosed sterile chamber with filtered air protection.

Sealing Under Sterile Conditions

Caps are applied in a contamination-free environment.

Because the filling occurs at room temperature, aseptic systems allow greater flexibility in packaging materials.

Typical Applications

Aseptic systems are suitable for:

Low-acid juices

Dairy-based beverages

Functional drinks

Premium export beverages

Key Features

Clean-room or sterile chamber design

High-level automation

Advanced sterilization control systems

Lightweight bottle compatibility

An automatic juice filling machine with aseptic technology offers extended shelf life without the need for refrigeration.

Technical Comparison: Hot Filling vs. Aseptic Filling

Understanding the differences between these two systems is essential for investment planning.

1. Filling Temperature

Hot juice filling machine: High-temperature filling (85–95°C)

Aseptic juice filling machine: Ambient-temperature filling in sterile environment

2. Bottle Requirements

Hot filling requires heat-resistant PET bottles with reinforced structure.

Aseptic filling allows lightweight PET bottles since no high heat is applied during filling.

3. Shelf Life

Hot filling typically provides 6–12 months shelf life for acidic beverages.

Aseptic filling can achieve extended shelf life for both low-acid and high-acid products.

4. Product Compatibility

Hot filling is best for acidic juices like mango and litchi.

Aseptic filling accommodates a wider range of beverages, including dairy-based drinks.

5. Equipment Complexity

Hot filling systems have relatively simpler mechanical structures.

Aseptic systems are highly complex, requiring sterile chambers and precise environmental control.

6. Energy Consumption

Hot filling consumes more thermal energy due to heating and cooling stages.

Aseptic filling consumes energy for sterilization systems and air filtration.

Investment and Operating Cost Comparison

Initial Equipment Investment

Hot juice filling machine: Lower capital investment, making it suitable for startups and mid-sized producers.

Aseptic juice filling machine: Higher initial investment due to sterile systems and UHT integration.

Operating Costs

Hot filling systems involve:

Steam consumption

Cooling water usage

Slightly heavier bottle materials

Aseptic systems involve:

Hydrogen peroxide sterilization systems

Air filtration systems

Strict maintenance requirements

Although aseptic systems have higher initial costs, they may support premium pricing strategies in certain markets.

Production Line Configuration Differences

Hot Filling Line Includes:

Juice processing system

3-in-1 bottle juice filling machine

Bottle inversion unit

Cooling tunnel

Labeling and packaging systems

Aseptic Filling Line Includes:

UHT sterilizer

Aseptic buffer tank

Sterile filling machine

Clean-room or sterile chamber

Bottle sterilization unit

The aseptic line typically requires more space and more sophisticated infrastructure.

Advantages and Disadvantages

Hot Juice Filling Machine

Advantages:

Lower investment cost

Mature and proven technology

Easier maintenance

Ideal for mango juice filling machine and litchi juice filling machine lines

Disadvantages:

Limited to high-acid beverages

Heavier bottle design required

Higher thermal energy consumption

Aseptic Juice Filling Machine

Advantages:

Suitable for low-acid beverages

Longer shelf life

Lightweight bottle compatibility

Premium market positioning

Disadvantages:

Higher capital investment

Complex operation

Strict sterilization management required

Which Solution Is Right for Your Business?

Choosing between a hot juice filling machine and an aseptic juice filling machine depends on several factors:

Product type (acidic vs. low-acid)

Target market positioning

Budget constraints

Production capacity requirements

Long-term brand strategy

For startups or manufacturers focusing on high-acid fruit juices, a hot filling solution often provides the best balance between cost and performance.

For premium beverage brands, export-focused companies, or producers of dairy-based drinks, aseptic technology may offer greater flexibility and market value.

Conclusion

Both the hot juice filling machine and the aseptic juice filling machine offer distinct advantages depending on production needs and market goals. Hot filling is a cost-effective and stable solution for acidic beverages such as mango and litchi juice, while aseptic filling provides flexibility and extended shelf life for a broader range of products.

Carefully evaluating product type, budget, and long-term strategy will help manufacturers select the most suitable automatic juice filling machine for their operations.

With extensive experience in beverage equipment manufacturing, King Machine provides advanced bottle juice filling machine solutions, including both hot filling and aseptic systems. By combining technical expertise with customized production line design, King Machine supports juice producers worldwide in achieving efficient, reliable, and high-quality beverage production.