The global carbonated beverage industry continues to expand, with sparkling water, soft drinks, energy drinks, and flavored sodas gaining popularity across diverse markets. As competition intensifies, beverage manufacturers must carefully choose not only their product formulations but also their packaging formats and production equipment.

Two dominant packaging options define the carbonated beverage sector: PET bottles and aluminum cans. Each format requires a specialized filling system—either a CSD filling machine designed for bottles or a canned CSD filling machine designed for aluminum containers. Understanding the technical, operational, and financial differences between these two solutions is essential for making the right investment decision.

This article provides a comprehensive comparison of PET bottle and can filling systems to help beverage producers determine which solution best aligns with their production goals.

1. Overview of CSD Filling Technologies

What Is a CSD Filling Machine?

A CSD filling machine (Carbonated Soft Drink filling machine) is specifically engineered to handle beverages containing dissolved CO₂. These machines use isobaric (counter-pressure) filling technology to maintain pressure equilibrium between the product tank and the container during filling. This prevents excessive foaming and preserves carbonation levels.

A typical PET bottle carbonated drinks filling machine integrates rinsing, filling, and capping into a 3-in-1 monoblock system. It is widely used for:

Sparkling water

Carbonated soft drinks

Flavored soda

Large-volume family packs

What Is a Canned CSD Filling Machine?

A canned CSD filling machine is designed for aluminum cans and integrates filling and seaming processes. Like bottle systems, it uses counter-pressure technology but incorporates specialized foam control and can seaming mechanisms to ensure airtight sealing.

Canned systems are often used for:

Energy drinks

Premium soda brands

Craft beverages

Export-oriented products

2. PET Bottle CSD Filling Machine: Features and Advantages

Technical Characteristics

A modern carbonated drink filling machine for PET bottles typically includes:

Isobaric filling valves

3-in-1 monoblock (rinsing–filling–capping)

Automatic cap sorting and feeding systems

PLC control with HMI touchscreen

Adjustable bottle neck handling mechanisms

The monoblock design reduces contamination risk and saves factory space while maintaining high production efficiency.

Advantages of PET Bottles

PET bottles offer several commercial and operational advantages:

Lower Packaging Cost

PET materials are generally less expensive than aluminum, especially in emerging markets.

Lightweight and Easy Transport

Reduced shipping costs compared to glass or cans.

Flexible Bottle Shapes

Custom bottle designs enhance brand differentiation.

Multiple Volume Options

Common sizes range from 330ml to 2L and above, making PET ideal for family consumption.

Ideal Applications

PET bottle carbonated soft drink filling machines are particularly suitable for:

Large-scale beverage factories

High-volume retail markets

Regions where cost efficiency is a priority

3. Canned CSD Filling Machine: Features and Advantages

Technical Characteristics

A canned CSD filling machine includes:

Counter-pressure filling system

High-speed filling valves

Integrated can seaming unit

Foam suppression control

Optional nitrogen dosing systems

The seaming process is critical. It ensures airtight closure and maintains internal pressure, preserving carbonation throughout the product’s shelf life.

Advantages of Aluminum Cans

Superior Barrier Protection

Aluminum provides complete protection against light and oxygen.

Premium Market Positioning

Cans often convey a modern, high-end brand image.

Rapid Cooling Performance

Aluminum cools faster than PET, improving consumer convenience.

High Recycling Rate

Aluminum is highly recyclable, making it attractive in sustainability-focused markets.

Ideal Applications

Canned systems are well-suited for:

Energy drinks

Craft sodas

Export-focused beverage brands

Premium retail channels

4. Technical Comparison: PET vs. Can Filling Systems

When evaluating a carbonated drinks filling machine, manufacturers must compare multiple technical and financial factors.

Container Cost

PET bottles: Lower material cost

Aluminum cans: Higher unit packaging cost

Equipment Investment

PET bottle CSD filling machine: Moderate initial investment

Canned CSD filling machine: Slightly higher investment due to seaming equipment

Filling Speed

Canned lines often achieve very high speeds in large-scale facilities. However, modern PET systems also offer competitive high-speed performance.

Shelf Life

Cans provide superior barrier protection, extending shelf life compared to PET bottles.

Branding Flexibility

PET allows for unique bottle shapes and ergonomic designs, while cans rely on printed surface branding.

5. Production Line Configuration Differences

PET Bottle Line Configuration

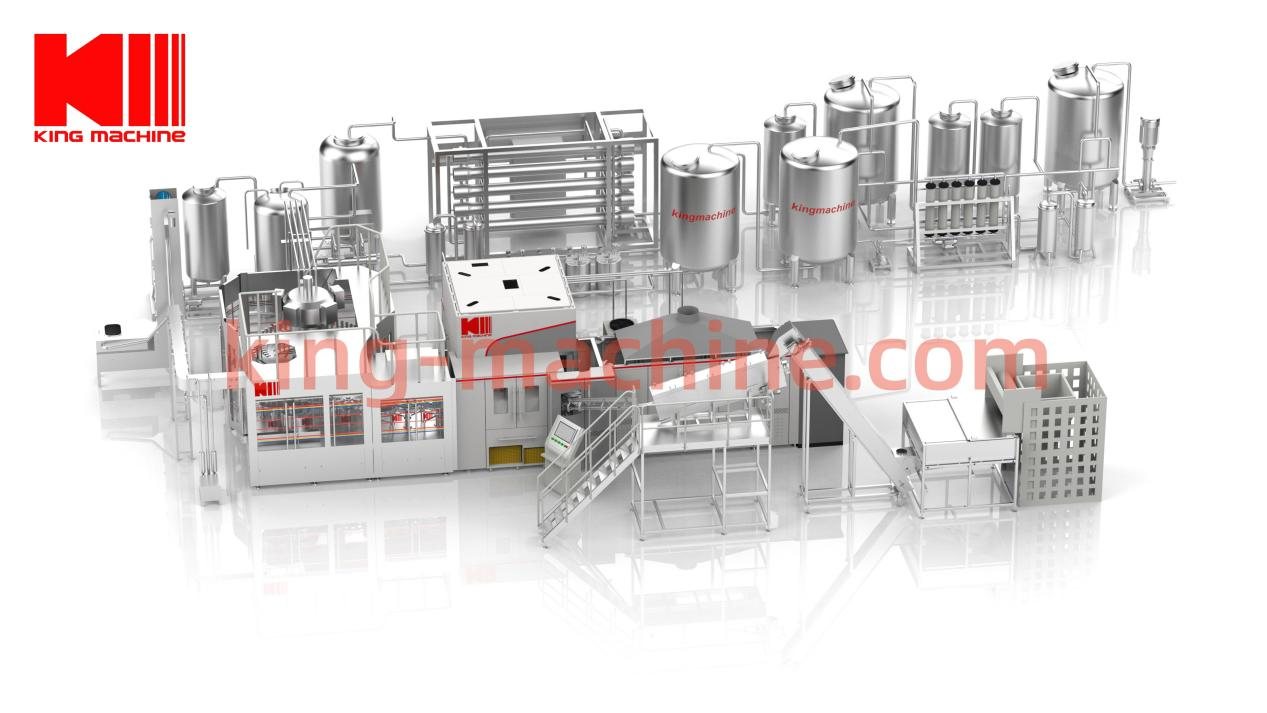

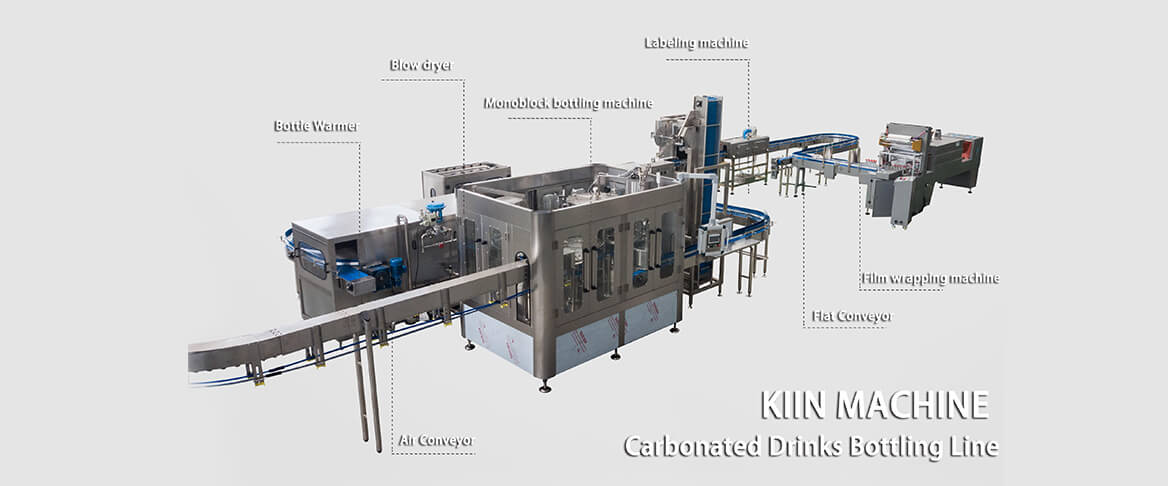

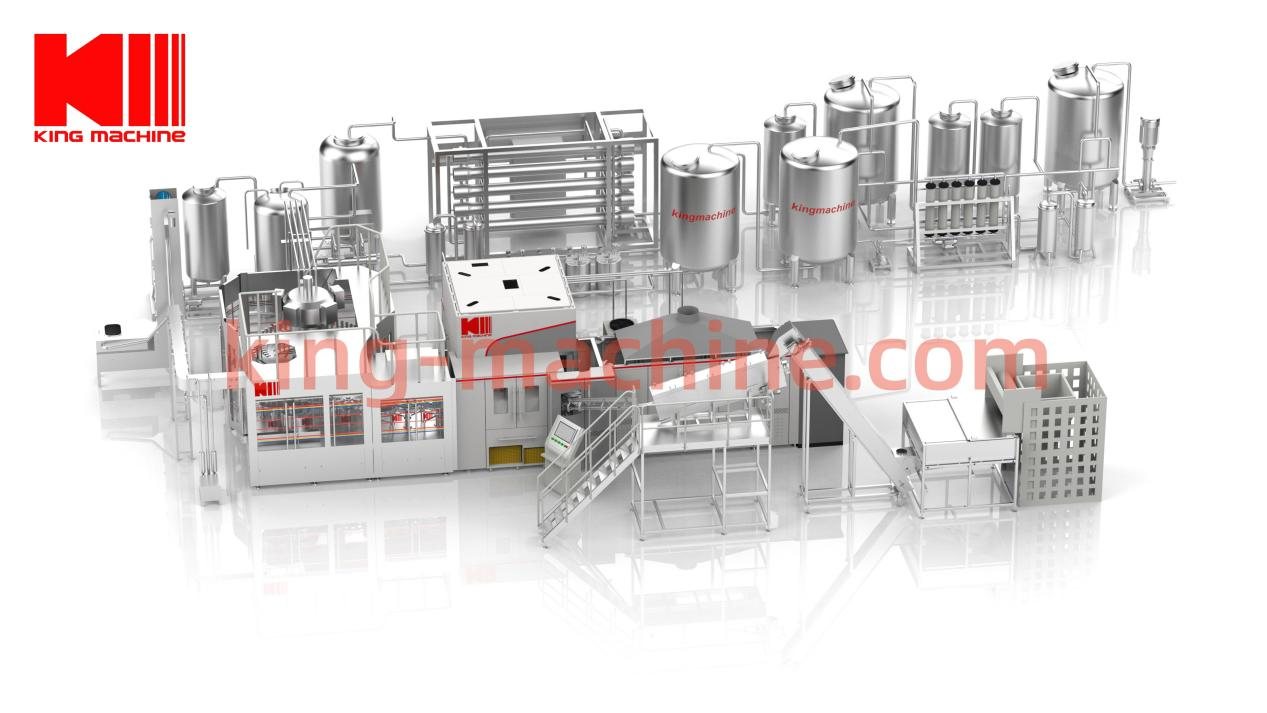

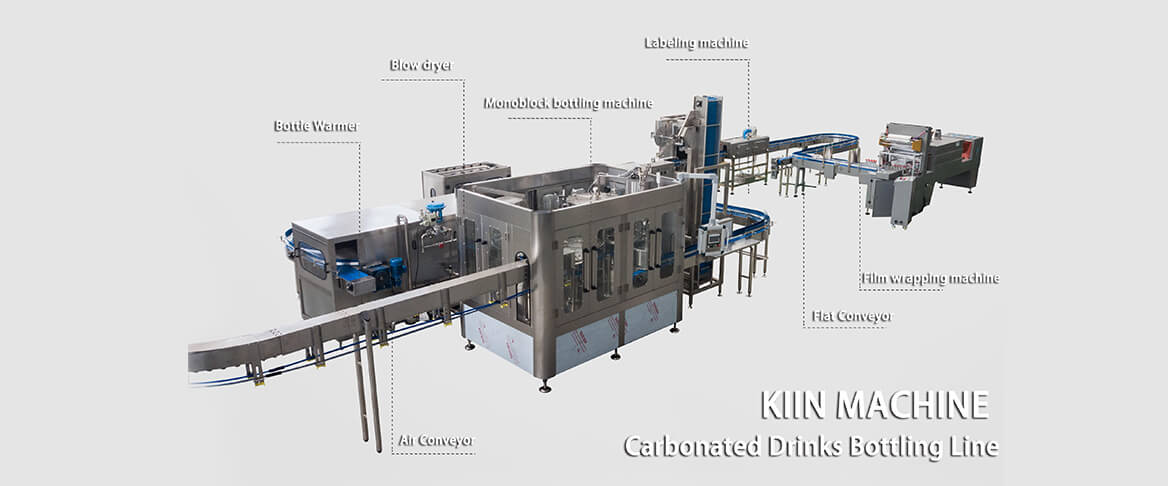

A complete PET bottle carbonated drink filling machine line typically includes:

PET blow molding machine

Air conveyor system

CSD filling machine (3-in-1 monoblock)

Labeling machine

Shrink wrapping or carton packing system

This configuration offers flexibility in bottle production and packaging design.

Can Line Configuration

A canned production line usually includes:

Can depalletizer

Can rinsing unit

Canned CSD filling machine

Seaming machine

Can warmer (optional)

Shrink packer or tray packer

Can lines often require precise synchronization between filling and seaming units.

6. Which Solution Is Right for Your Business?

The decision between a PET bottle carbonated soft drink filling machine and a canned CSD filling machine depends on several strategic factors:

Target consumer market

Product positioning (mass-market vs. premium)

Budget constraints

Expected production volume

Distribution channels

For large-volume, cost-sensitive markets, PET bottle systems may provide the best balance of flexibility and affordability. For high-end, export, or energy drink markets, canned systems may deliver stronger brand impact and longer shelf life.

Some advanced beverage manufacturers operate both PET and can lines to diversify product offerings and mitigate market risk.

Conclusion

Both PET bottle and aluminum can solutions offer unique advantages in carbonated beverage production. A CSD filling machine designed for PET bottles provides cost efficiency, packaging flexibility, and scalability. A canned CSD filling machine offers premium positioning, superior barrier protection, and strong appeal in competitive markets.

When evaluating equipment, manufacturers should carefully analyze technical performance, production efficiency, long-term operating costs, and overall return on investment. Choosing an experienced carbonated drink filling machine manufacturer is critical to ensuring stable performance, accurate pressure control, and reliable after-sales support.

As a professional supplier of advanced carbonated drinks filling machine systems, King Machine provides comprehensive solutions for both PET bottle and canned carbonated beverage production lines. With extensive industry expertise and global project experience, King Machine delivers high-performance CSD filling machines tailored to meet the evolving demands of beverage manufacturers worldwide.