In the beverage industry, juice filling production lines play a crucial role in ensuring high-quality, consistent, and efficient bottling of juice products. However, even the most advanced production systems can face operational issues over time. Downtime, leakage, or product contamination can affect production efficiency, increase costs, and harm brand reputation.

Understanding these common problems—and how to fix them—can help manufacturers keep production running smoothly, maintain product quality, and improve overall equipment effectiveness (OEE).

1. Inconsistent Filling Levels

One of the most frequent issues in juice filling lines is inconsistent filling volume. Some bottles may be underfilled, while others are slightly overfilled. This problem not only affects product quality but can also lead to non-compliance with labeling or packaging regulations.

Common Causes

Incorrect machine calibration or filling head misalignment.

Air bubbles or foam in the juice that interfere with the filling process.

Temperature fluctuations, especially with hot-fill juices, causing volume variation.

Wear or clogging in filling nozzles or valves.

How to Fix It

Regularly calibrate and adjust the filling heads based on the container type and product viscosity.

Use anti-foaming systems or design a pre-fill vacuum stage to eliminate air pockets.

Maintain a consistent product temperature during filling, especially for hot-fill lines.

Clean and inspect nozzles frequently to prevent build-up of pulp or sugar residue.

2. Leakage or Spillage During Filling

Leakage around filling nozzles, conveyor belts, or cap-sealing stations can cause product loss, sticky residue, and hygiene issues on the production line.

Common Causes

Loose or worn-out sealing gaskets.

Incorrect nozzle height or angle relative to bottle neck.

Poor synchronization between conveyor speed and filling rate.

Pressure imbalances in the filling tank.

How to Fix It

Regularly inspect seals, O-rings, and gaskets, replacing them before wear becomes critical.

Ensure proper bottle positioning using adjustable neck guides and timing screws.

Match the filling speed to bottle flow to prevent splashing or overflow.

Use an automated liquid-level sensor to control fill volume more precisely.

3. Foaming and Air Entrapment

Foaming is a typical challenge in juice filling—especially for fruit juices that contain pulp, sugar, or carbonation. Excess foam can cause fill-level variations, cap-sealing failures, and spillage.

Common Causes

High filling speed or turbulent liquid flow.

Inappropriate filling technique (top-down instead of bottom-up).

Lack of degassing before filling.

High product temperature.

How to Fix It

Implement a bottom-up filling system, allowing juice to enter gently along the bottle’s wall.

Use anti-foam agents approved for beverage applications.

Add a degassing or deaeration system to remove dissolved air before filling.

Reduce filling speed slightly when handling pulp-rich or viscous juices.

4. Contamination and Hygiene Issues

Maintaining product purity is critical in juice bottling. Contamination can lead to microbial growth, spoilage, or health hazards, resulting in product recalls and brand damage.

Common Causes

Inadequate cleaning of filling heads or pipelines.

Poorly maintained CIP (Cleaning-In-Place) systems.

Improper handling of juice concentrate or bottle sterilization.

Cross-contamination between juice types.

How to Fix It

Establish a strict CIP and SIP (Sterilization-In-Place) schedule after each production cycle.

Regularly inspect filters, pipes, and nozzles for residue build-up.

Use UV or ozone sterilization systems for bottles and caps before filling.

Ensure proper temperature control during pasteurization and filling to prevent bacterial growth.

Best Practice: For hot-fill lines, ensure filling temperature remains between 85–90°C to eliminate microbial contamination effectively.

5. Bottle Jams and Conveyor Misalignment

Mechanical blockages can occur at transfer points or during bottle accumulation, leading to downtime, breakage, or product waste.

Common Causes

Poor synchronization between conveyors and filling machines.

Variation in bottle dimensions or material thickness.

Faulty sensors or guide rails.

Dirt or sticky residue on conveyors.

How to Fix It

Adjust conveyor speed settings to match production flow.

Use bottle alignment systems or star wheels to guide containers accurately.

Clean conveyor belts regularly to remove debris or juice spills.

Verify sensor functionality and replace faulty units immediately.

Pro Tip: Choose bottle materials and shapes consistent with your filler’s design—lightweight PET bottles are more sensitive to alignment errors than glass bottles.

6. Temperature and Pressure Fluctuations

Juice filling often involves hot-fill processes or pressure-based filling for specific products. Temperature or pressure variations can lead to improper sealing, reduced shelf life, or deformation of bottles.

Common Causes

Faulty temperature sensors or controllers.

Inconsistent heating in pasteurization units.

Pressure leaks in the filling chamber.

How to Fix It

Calibrate and test temperature and pressure sensors regularly.

Monitor heating and cooling cycles using digital control systems.

Maintain an appropriate holding time at the required fill temperature for product stability.

Use insulated pipelines and tanks to minimize heat loss.

Automation Advantage: Integrating temperature and pressure control into the machine’s PLC system allows real-time adjustments and improved consistency.

7. Inaccurate Capping and Sealing

Faulty capping can lead to leakage, loss of carbonation (for juice drinks), or contamination. In automated juice filling lines, this is often caused by misaligned caps, worn parts, or torque issues.

Common Causes

Cap feeding system malfunction.

Inconsistent torque or sealing force.

Wear in capping heads or chucks.

How to Fix It

Clean and lubricate capping heads routinely.

Use a torque tester to ensure proper cap tightness.

Synchronize the cap sorting and feeding system with conveyor speed.

Replace worn-out components promptly.

8. Preventive Maintenance: The Key to Long-Term Efficiency

Most juice filling production issues can be prevented with a structured preventive maintenance program. Instead of reacting to breakdowns, schedule regular inspections, lubrication, calibration, and cleaning.

Key Steps:

Create a daily checklist for operators to detect visible leaks, noise, or irregular motion.

Conduct monthly machine calibration and performance audits.

Maintain a spare parts inventory for quick replacement.

Train staff in basic troubleshooting and machine safety.

9. Upgrading to Smart Automation Systems

To minimize downtime and enhance quality control, modern juice filling lines increasingly rely on automated monitoring systems.

Smart sensors, PLCs, and IoT-enabled controls provide:

Real-time data tracking on temperature, flow rate, and pressure.

Predictive maintenance alerts to prevent failures.

Automatic adjustment to maintain optimal filling accuracy.

If your existing production line frequently experiences stoppages, upgrading to a fully integrated system can significantly improve productivity and reduce long-term costs.

Conclusion

Running a smooth and efficient juice filling line requires more than just advanced machinery—it demands consistent monitoring, skilled maintenance, and process optimization. By addressing common issues such as inconsistent fills, contamination, foaming, and temperature instability, manufacturers can improve both output and product quality.

Whether you operate a small-scale juice bottling plant or a large commercial facility, regular maintenance, smart automation, and a proactive approach to troubleshooting will help you keep production flowing without interruption.

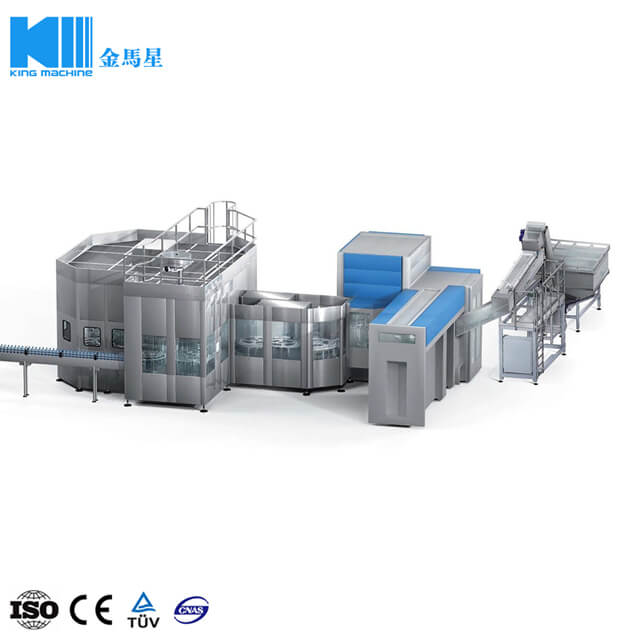

For advanced, efficient, and reliable juice filling systems, partner with King Machine.

With years of experience in the PET plastic packaging industry, King Machine provides integrated solutions for beverage production, combining preform feeding, blowing, labeling, filling, and capping into one streamlined system. Our expert team and intelligent machinery deliver continuous production optimization—helping you achieve higher efficiency, consistent quality, and sustainable growth.