At first glance, bottled water may appear to be a simple product. In reality, still water, carbonated water, and mineral water each present unique physical, chemical, and regulatory characteristics that directly influence filling technology requirements. Selecting the wrong filling method can lead to excessive foaming, inaccurate fill levels, product quality degradation, or even regulatory non-compliance.

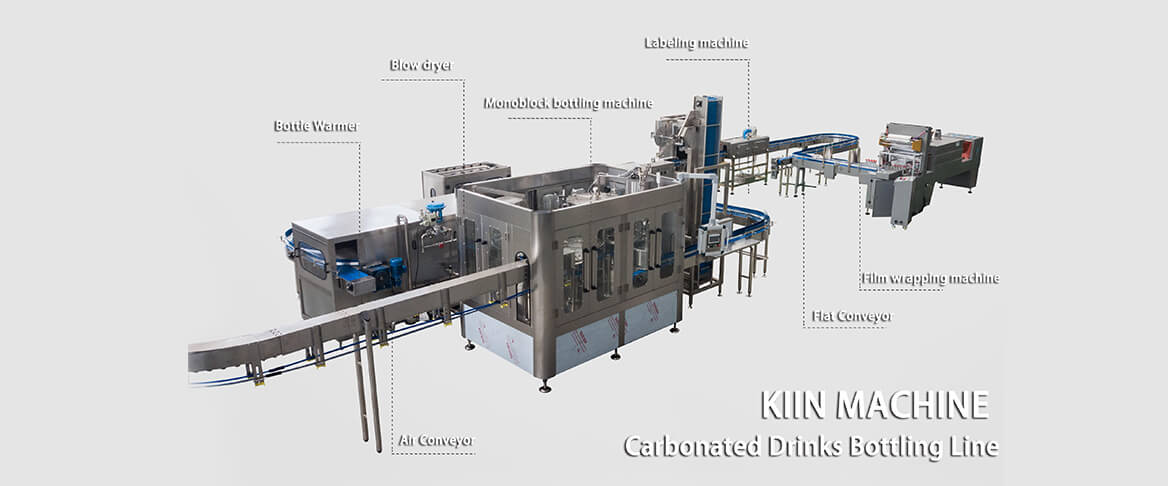

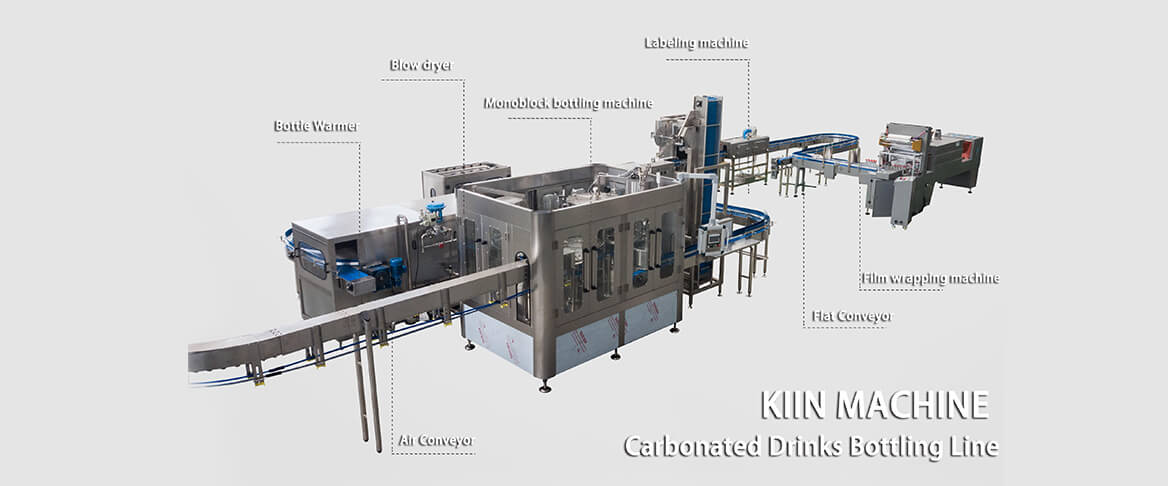

Modern beverage producers must align filling technology with water type, packaging format, and production capacity. From gravity-based water filling machines to sophisticated isobaric carbonated soft drink filling machines, each solution is engineered for specific performance conditions. Understanding these differences is essential for building efficient, hygienic, and future-ready water filling lines.

This article explains the filling technology requirements for still water, carbonated water, and mineral water, highlighting key differences in equipment design, process control, and operational considerations.

1. Overview of the Three Main Water Categories

Still Water (Non-Carbonated Water)

Still water refers to purified or treated drinking water without added carbon dioxide. It includes purified water, spring water, and treated municipal water. Still water is commonly packaged in PET bottles ranging from small single-serve sizes to large-volume containers.

Because still water has no internal pressure, it is the least complex product to fill, but high-speed production still requires precision and hygiene.

Carbonated Water

Carbonated water contains dissolved CO₂, which creates internal pressure inside the bottle. This category includes soda water, sparkling water, and flavored carbonated drinks. Carbonation introduces challenges related to foaming, pressure control, and carbonation retention.

Carbonated water filling requires specialized equipment capable of maintaining pressure balance throughout the filling process.

Mineral Water

Mineral water is defined by its natural mineral content and source. Unlike purified water, mineral water must retain its original composition, which limits processing methods. Filling technology must preserve mineral balance, taste, and compliance with labeling and regulatory requirements.

2. Filling Technology Requirements for Still Water

Recommended Filling Methods

Still water is typically filled using:

Gravity filling, suitable for basic applications

Flow-meter filling, offering higher accuracy

Volumetric filling, used when precise dosing is required

Modern water filling machines often combine flow-meter technology with high-speed automation to achieve accurate and stable filling.

Key Technical Requirements

Key technical requirements for still water filling include:

High filling accuracy to reduce product loss

Stable flow control at high speeds

Minimal splashing to avoid bottle wetting

Even without carbonation, improper control can result in inconsistent fill levels and reduced line efficiency.

Hygiene and Material Considerations

Still water filling lines must meet food-grade hygiene standards. Equipment is typically manufactured from stainless steel, with smooth surfaces and minimal dead zones. CIP (Clean-in-Place) systems are essential for regular sanitation.

Typical Challenges and Solutions

Common challenges include dripping, bottle deformation at high speeds, and inconsistent flow. Advanced water filling machines address these issues through optimized valve design and servo-controlled filling systems.

3. Filling Technology Requirements for Carbonated Water

Characteristics That Affect Filling

Carbonated water contains dissolved CO₂ that becomes unstable when pressure or temperature changes. During filling, improper handling can cause excessive foaming, carbonation loss, and inaccurate fill levels.

Temperature control is critical—carbonated beverages are typically filled at low temperatures to improve CO₂ retention.

Isobaric Filling Technology Explained

Carbonated water is filled using isobaric filling technology, which maintains equal pressure between the filling tank and the bottle. Before filling, the bottle is pre-pressurized with CO₂ to match tank pressure.

This pressure balance allows liquid to flow smoothly without excessive foaming, making isobaric systems essential in carbonated soft drink filling machines.

Foaming Control Techniques

Effective foaming control includes:

Low-temperature filling

Optimized filling valve geometry

Precise pressure regulation

Controlled filling speed

Advanced carbonated soft drink filling machines integrate these features to ensure stable, high-speed operation.

Key Equipment Considerations

Carbonated filling systems require:

Isobaric filling valves

CO₂ recovery and recycling systems

High-performance capping units

Equipment design directly affects carbonation retention and product consistency.

4. Filling Technology Requirements for Mineral Water

Unique Properties of Mineral Water

Mineral water contains naturally occurring minerals such as calcium, magnesium, and sodium. These components contribute to taste and health claims, making preservation of composition a top priority.

Gentle Filling and Minimal Processing

Mineral water filling emphasizes gentle handling. Excessive filtration, pressure changes, or aggressive cleaning processes can alter mineral balance. Mineral water filling machines are designed to minimize product stress.

Material and Equipment Compatibility

Mineral content can increase the risk of corrosion or scaling. As a result, mineral water filling machines use corrosion-resistant materials and specially designed valves to ensure long-term reliability.

Regulatory and Labeling Implications

Mineral water is subject to strict regulations regarding source protection, processing, and labeling. Filling equipment must support compliance by maintaining hygienic integrity and traceability.

5. Comparison of Filling Technologies: Still vs. Carbonated vs. Mineral Water

Key differences include:

Filling pressure: atmospheric for still water, pressurized for carbonated water

Valve design: simple flow valves vs. isobaric valves

Process complexity: low for still water, high for carbonated products

Hygiene sensitivity: especially high for mineral water

Understanding these distinctions helps manufacturers select the correct water filling machine configuration.

6. Bottle, Cap, and Packaging Considerations

Bottle design plays a critical role in filling performance. Carbonated water bottles must withstand internal pressure, while mineral water bottles must preserve taste neutrality. Cap sealing performance is equally important, especially for pressurized products.

Proper coordination between bottle design, cap type, and filling technology ensures product safety and shelf stability.

Conclusion

Still water, carbonated water, and mineral water each require specialized filling technology. From simple gravity-based water filling machines to advanced isobaric carbonated soft drink filling machines and gentle mineral water filling machines, correct equipment selection is essential for product quality, efficiency, and compliance.

As a leading expert in the PET plastic packaging and beverage filling industry, King Machine provides comprehensive solutions covering Water Filling Machines, Mineral Water Filling Machines, and Carbonated Soft Drink Filling Machines, helping water producers worldwide build reliable, efficient, and high-quality filling lines.