The global carbonated beverage market continues to expand, driven by strong consumer demand for sparkling water, soft drinks, flavored soda, and energy beverages. For manufacturers, production efficiency and product quality depend heavily on selecting the right carbonated soft drink filling machine. Unlike still beverage systems, carbonated filling requires precise pressure control, CO₂ retention management, and high-speed stability.

Investing in the wrong equipment can lead to excessive foaming, carbonation loss, unstable filling accuracy, high maintenance costs, and production downtime. Therefore, understanding the key technical features of a modern carbonated drink filling machine is essential for maximizing long-term return on investment.

Below are the top features beverage producers should carefully evaluate before purchasing a CSD filling system.

1. Isobaric (Counter-Pressure) Filling Technology

The most critical feature of any CSD filling machine is isobaric filling technology.

Carbonated beverages contain dissolved CO₂ under pressure. If filling occurs under atmospheric conditions, rapid pressure changes cause foaming and carbonation loss. An isobaric filling system ensures that the pressure inside the bottle matches the pressure inside the filling tank before product enters the container.

Key benefits include:

Minimal CO₂ loss

Reduced foaming

Stable fill levels

Improved product shelf life

A high-quality carbonated soft drink filling machine should include precision pressure control valves and automatic pressure equalization systems to maintain consistent carbonation levels throughout production.

2. High-Speed and Stable Production Capacity

Production capacity is a decisive factor when selecting a carbonated drink filling machine. Modern beverage lines often operate between 6,000 and 36,000 bottles per hour (BPH), depending on market demand.

Important considerations include:

Servo-driven systems for precise motion control

High-speed filling valves

Stable conveyor synchronization

Minimal vibration during high-speed operation

A well-designed CSD filling machine maintains consistent output without compromising filling accuracy or carbonation retention. Stability is more important than peak speed; unstable high-speed systems often lead to product waste and mechanical wear.

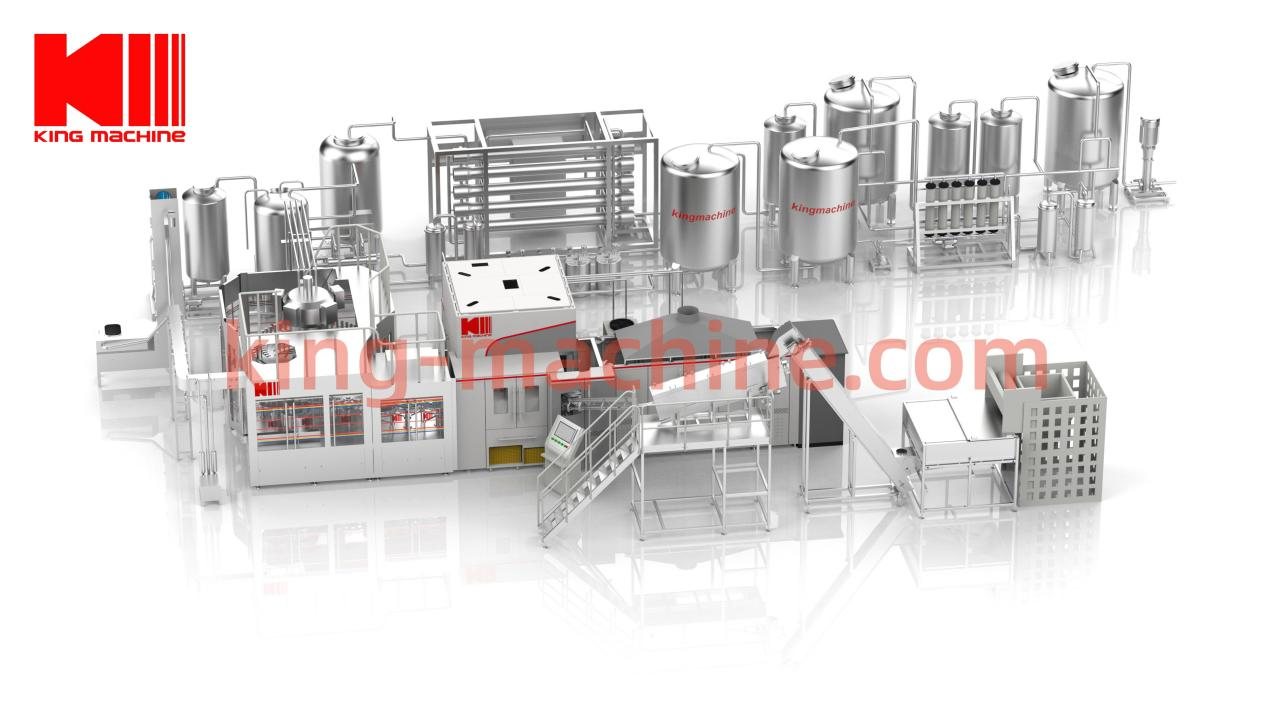

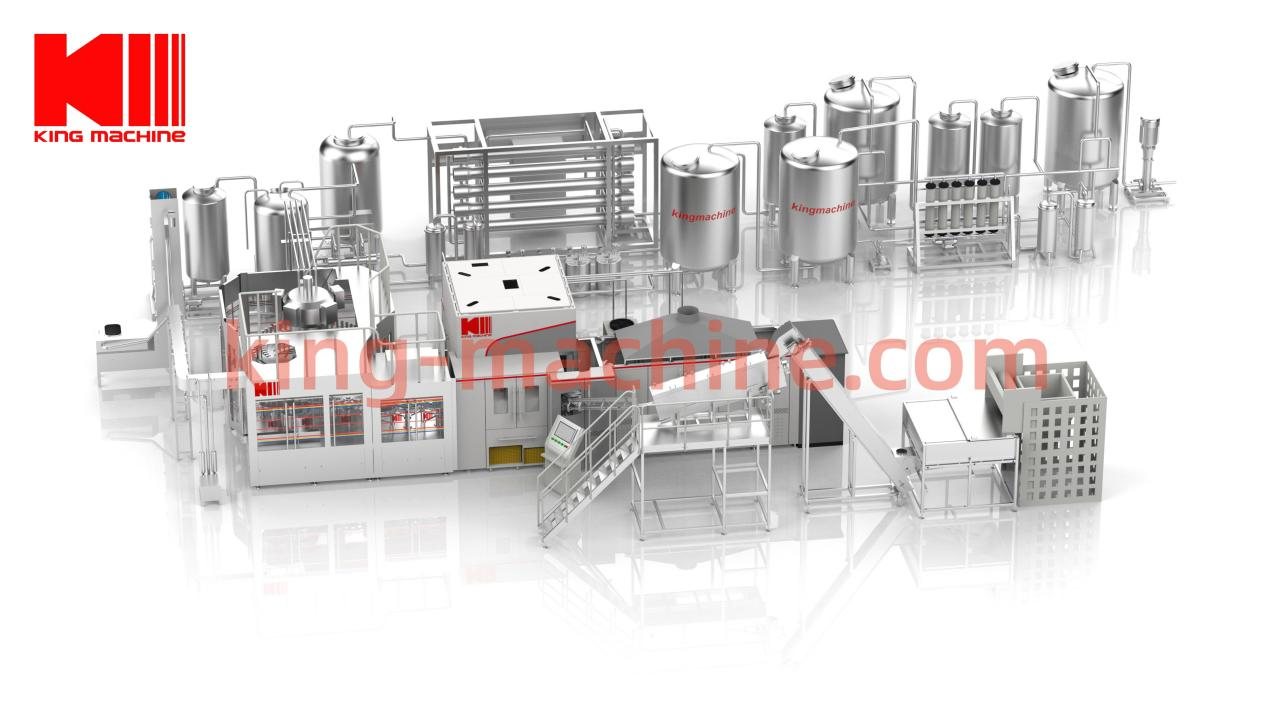

3. Integrated Monoblock Design (3-in-1 or 4-in-1)

Most modern carbonated beverage lines use an integrated monoblock system that combines:

Bottle rinsing

Filling

Capping

Some systems also integrate bottle sterilization or pre-evacuation functions.

A 3-in-1 monoblock carbonated soft drink filling machine offers several advantages:

Reduced floor space

Lower contamination risk

Improved production flow

Simplified operation and maintenance

Compared to standalone machines, integrated systems provide higher efficiency and better hygiene control, making them ideal for medium- to large-scale beverage production facilities.

4. Advanced CO₂ Control and Pressure Regulation

Precise CO₂ management directly impacts beverage taste, texture, and quality. An advanced carbonated drink filling machine should include:

Digital pressure sensors

Automatic pressure regulation

CO₂ back-pressure control

Adjustable filling pressure parameters

Automated pressure regulation ensures consistent carbonation levels across all bottles. It also reduces CO₂ consumption, which significantly lowers operational costs over time.

This feature is particularly important for manufacturers producing multiple beverage formulations with different carbonation requirements.

5. Hygienic Design and Food Safety Compliance

Food safety remains a top priority in beverage production. A high-quality carbonated soft drink filling machine must comply with international hygiene standards.

Key hygienic features include:

SUS304 or SUS316 stainless steel construction

Food-grade seals and gaskets

Sanitary pipelines and valves

Integrated CIP (Clean-in-Place) systems

CIP systems allow automatic cleaning of filling valves and product pipelines without disassembly, reducing downtime while maintaining strict sanitation standards.

When evaluating a carbonated drink filling machine manufacturer, always verify compliance with relevant food safety certifications and material standards.

6. Flexible Bottle Compatibility

Market demand often requires production flexibility. Beverage producers may need to switch between different bottle sizes or container types.

A modern CSD filling machine should support:

Various PET bottle sizes

Glass bottles (if applicable)

Quick mold change systems

Adjustable neck handling mechanisms

Quick changeover capability reduces downtime and increases production versatility, allowing manufacturers to respond rapidly to market changes.

7. Automation and Intelligent Control Systems

Automation significantly enhances production efficiency and reduces human error.

Advanced control features include:

PLC-based control systems

Touchscreen HMI interfaces

Real-time production monitoring

Automatic fault detection and alarms

Data logging for performance analysis

An intelligent carbonated soft drink filling machine provides operators with precise control over filling parameters, pressure settings, and speed adjustments.

Data collection also supports preventive maintenance strategies, helping to reduce unexpected downtime.

8. Energy Efficiency and Resource Optimization

Energy costs and sustainability considerations are becoming increasingly important in beverage manufacturing.

An energy-efficient carbonated drink filling machine should include:

Low-energy servo motors

Optimized compressed air consumption

Efficient rinsing systems to reduce water usage

Smart power management systems

Reducing energy and resource consumption not only lowers operating costs but also aligns with environmental sustainability goals, which are increasingly important for global beverage brands.

9. High-Precision Filling and Capping Systems

Filling accuracy directly affects product consistency and profitability.

Key precision features include:

High-accuracy filling valves

Stable liquid level control

Automatic level correction systems

Torque-controlled capping heads

Precise filling reduces product waste and ensures uniform bottle appearance, which enhances brand image and consumer trust.

Reliable capping systems prevent leakage, maintain internal pressure, and preserve carbonation during distribution.

Conclusion

Selecting the right carbonated drink filling machine requires careful evaluation of technical performance, automation capabilities, hygiene standards, and manufacturer expertise. Isobaric filling technology, advanced pressure control, high-speed stability, intelligent automation, and energy efficiency are all critical features that determine long-term production success.

For beverage manufacturers aiming to produce high-quality sparkling water, soda, and carbonated soft drinks efficiently, investing in a reliable and technologically advanced carbonated soft drink filling machine is essential.

As an experienced carbonated drink filling machine manufacturer, King Machine provides advanced CSD filling machine solutions designed for precision, efficiency, and long-term operational stability. With extensive expertise in beverage production systems, King Machine delivers high-performance carbonated soft drink filling machines tailored to meet the evolving needs of global beverage producers.