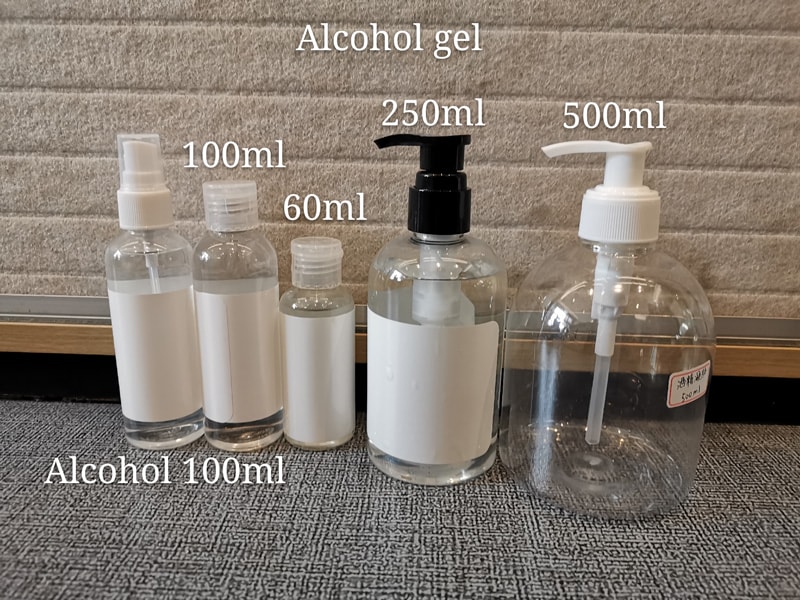

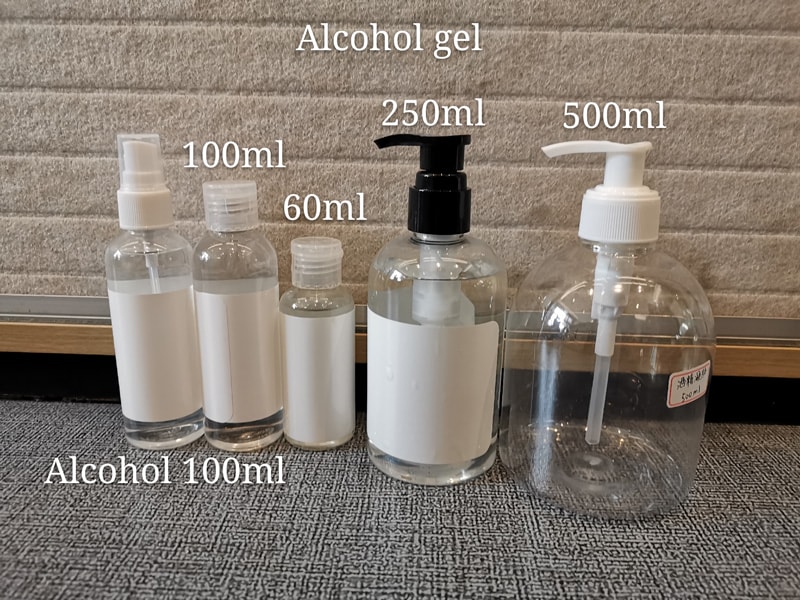

Complete line from A-to-Z to do Sanitizer

Full line from blow molding of bottles as mentioned above 100 ML all the way to 2000 ML with a filling line labeling line all the way to a packing line

Sanitizer & Alcohol Gel. Suitable :

Sanitizer, Alcohol Gel,detergent, shampoo, dishwasher, liquid soap, bleach, clorox, toilet cleaner .etc

Bottle Material : PE PP Bottle

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker Label |

Sanitizer filling machine is a kind of Piston filling machine, it is an advanced filling equipment for hand washing liquid and washing products based on the characteristics of the hand washing liquid with thick and slightly corrosive characteristics.

Sanitizer filling machine |

|  Alcohol Gel filling machine |

|  Piston filling machine |

Features.

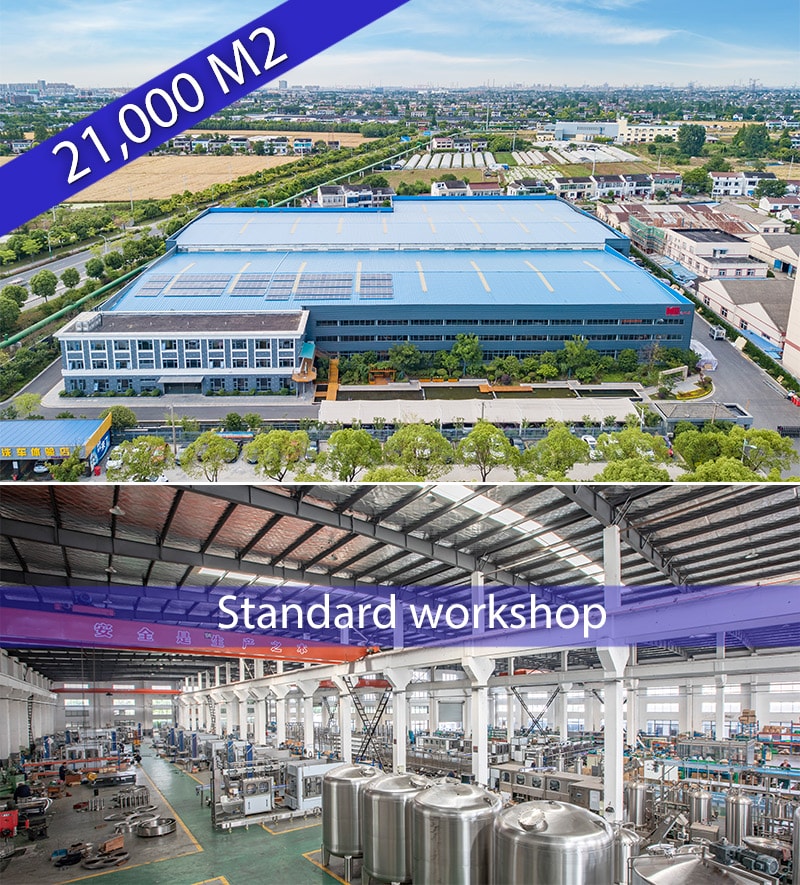

1. High degree of automation, easy operation, stable operation, can effectively save corporate costs and improve production efficiency.

2. Each single machine can complete its work independently. It has independent operating system and electrical components such as numerical control display to control and adjust various parameters and display settings. Can help companies achieve standardized production

3. The individual machines are linked and separated quickly, and the adjustment is fast and simple, so that each process of production can be coordinated.

4. Each single machine can adapt to the packaging of various specifications of bottles, with few adjustment parts.

5. This packaging production line adopts international new process design and meets GMP standards.

6.The production line runs smoothly, each function is easy to combine, and the maintenance is convenient. Various production combinations can be performed according to the user's respective product process requirements.

Output

40PCS/MIN

Products that can be processed

-Iodine

-Disinfectant Spray

-Sanitizer

*We supply complete solution for the Sanitizer production, including Bottle Inlet Machine /Automatic washing machine 12heads / Automatic filling and capping sealing machine / Core plate / Pump head vibration disk / Outer cover vibrating plate / Ultrasonic liquid level controller, plunger type barrel pump

Bottle Inlet Machine | |  Automatic Washing Machine | |  Automatic filling capping sealing machine |