In the competitive world of beverage manufacturing, efficiency, precision, and hygiene are key factors that determine product quality and operational success. A juice filling line is at the heart of any juice production facility, ensuring that every bottle is cleaned, filled, and sealed with consistency and care. From rinsing to capping, each stage in the process plays a critical role in maintaining product integrity and maximizing throughput.

This article takes an in-depth look at the key equipment used in a modern juice filling line, explaining how each component contributes to a streamlined, high-performance production process.

1. What is a Juice Filling Line

A typical juice filling line is designed to transform raw materials into ready-to-ship bottled beverages through a series of carefully synchronized processes. The workflow generally includes:

Bottle rinsing – Cleaning and sterilizing empty containers before filling.

Filling – Accurately dispensing juice into bottles while maintaining hygiene.

Capping – Sealing bottles to prevent leakage and contamination.

Labeling and packaging – Applying product information and preparing bottles for distribution.

Modern juice filling lines also incorporate automation, data collection, and cleaning systems such as CIP (Clean-In-Place) to ensure safe, efficient, and continuous production. The integration of these technologies helps beverage producers maintain high standards of quality and efficiency while reducing labor and maintenance costs.

2. Bottle Rinsing System

Function and Importance

Before filling, bottles must be thoroughly cleaned to remove dust, debris, or any contaminants that could affect product quality. A bottle rinsing machine performs this essential task by inverting bottles and flushing them with clean air, water, or sterilizing agents.

Types of Rinsing Systems

Water Rinsers: Use filtered or ionized water to clean bottles, suitable for most production lines.

Air Rinsers: Employ compressed air to blow away light particles, ideal for lightweight PET bottles.

Ionized Air Rinsers: Combine air and ionization to neutralize static and improve cleaning performance—often used in aseptic environments.

Key Features

Rotary design with multiple rinsing heads for high throughput.

Adjustable bottle holders for different bottle shapes and sizes.

Integrated drainage system to recover and recycle rinsing media.

By ensuring every container is clean before filling, the rinsing system lays the foundation for hygienic production and extended shelf life.

3. Juice Filling Machine

Role in the Juice Filling Line

The juice filling machine is the centerpiece of the entire production line. It determines both the efficiency and accuracy of the process, directly influencing product consistency and cost control.

Depending on the product type and temperature requirements, juice filling machines can operate under different principles.

Common Filling Methods

Hot Filling: Ideal for pasteurized juices and beverages that require sterilization. Bottles are filled at high temperatures and sealed immediately.

Cold or Aseptic Filling: Used for fresh or sensitive juices that need to be processed in sterile environments at lower temperatures.

Gravity or Isobaric Filling: Suited for clear or low-viscosity liquids, ensuring smooth, foam-free filling.

Main Components

Filling nozzles: Control liquid flow and filling precision.

Product tank: Maintains juice at the desired temperature and pressure.

Sensors and flow meters: Monitor filling levels in real time.

Advantages of Modern Filling Systems

Advanced filling systems are equipped with servo motors and PLC-controlled mechanisms for precise fill levels. They also feature automated cleaning, temperature control, and data tracking functions. These technologies minimize product loss, reduce contamination risk, and improve overall production consistency.

4. Capping Machine

Once bottles are filled, they are immediately transferred to the capping machine, which applies and tightens caps securely. Proper capping is critical to maintain product freshness and prevent leakage or microbial contamination.

Types of Capping Systems

Screw Capping Machines: Most common type for PET bottles with threaded caps.

Press-On Capping Machines: Suitable for snap-fit closures.

ROPP Cappers: Used for metal caps, particularly in glass bottle packaging.

Key Features

Automatic cap sorting and feeding system to ensure continuous operation.

Torque control mechanism to ensure consistent sealing without damaging the cap or bottle.

Fault detection system that rejects improperly capped bottles.

Modern capping machines operate at high speeds and can handle a variety of cap designs and materials, ensuring that every bottle leaves the production line securely sealed.

5. Labeling, Coding, and Packaging Units

After sealing, bottles move to the labeling and packaging section of the line. This stage ensures that every product is correctly identified, traceable, and ready for retail presentation.

Labeling

Automatic labeling machines apply product labels quickly and precisely, whether they are wrap-around, sleeve, or self-adhesive types. These machines can handle bottles of different shapes and materials, maintaining alignment even at high speeds.

Coding and Marking

Date coders and batch printers mark bottles with production dates, batch numbers, or QR codes. This information is vital for traceability, compliance, and inventory management.

Packaging

Once labeled and coded, bottles are grouped and packed for transport using:

Shrink wrapping machines for bundling multiple bottles.

Cartoning systems for placing bottles into boxes.

Palletizing robots for final stacking and storage.

Automation in this stage minimizes human handling and ensures faster, safer packaging.

6. Auxiliary and Support Systems

A reliable juice filling line also includes several supporting systems that ensure smooth, safe, and efficient operation.

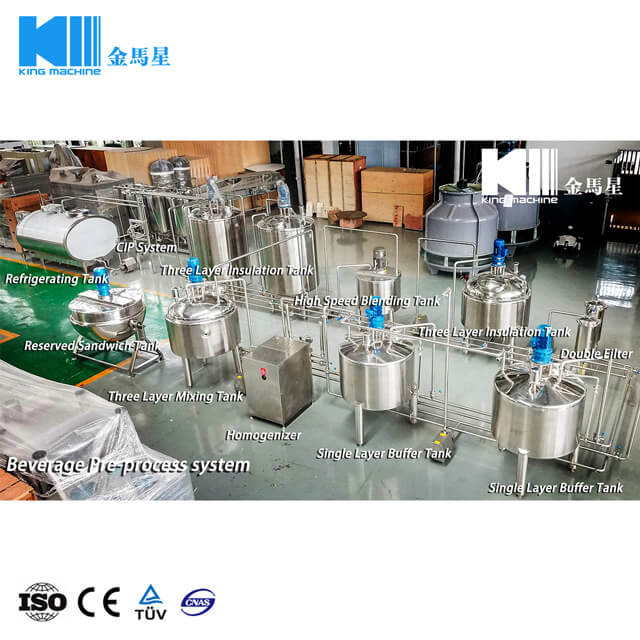

CIP (Cleaning in Place) System

The CIP system automatically cleans and sterilizes the interior of tanks, pipes, and filling nozzles without requiring manual disassembly. This system helps maintain hygiene standards and reduces downtime between product changes.

Sterilization Units

For aseptic production lines, UV, ozone, or steam sterilizers are used to sanitize bottles, caps, and air supply systems, ensuring the entire filling process remains contamination-free.

Conveyor and Transfer Systems

Air conveyors and bottle transfer systems connect each machine, maintaining smooth bottle flow and consistent line speed.

Inspection Systems

Automatic vision inspection systems check for fill level accuracy, proper sealing, and label placement—rejecting defective products before they leave the factory.

7. Integration and Control Systems

At the heart of every modern juice filling line is an integrated control system, often powered by PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) technology.

Benefits of Automation Integration

Real-time monitoring of temperature, fill volume, and pressure.

Automatic fault detection to reduce downtime.

Data analytics for production optimization.

Energy efficiency and reduced operator intervention.

These intelligent control systems allow for centralized management and improved traceability, making the entire production process more transparent and efficient.

8. Choosing the Right Equipment for Your Juice Line

Selecting the right equipment depends on several key factors:

Juice type: Clear, pulpy, cold-pressed, or carbonated beverages each require different filling conditions.

Production capacity: Match machine speed and design with expected output volume.

Hygiene requirements: Hot-fill or aseptic lines must meet strict sanitation standards.

Automation level: Determine whether a fully automatic or semi-automatic system suits your operational scale.

Partnering with an experienced equipment manufacturer ensures that all components are properly integrated for long-term reliability and performance.

Conclusion

A juice filling line is more than a series of machines—it’s a coordinated system designed to ensure product safety, quality, and consistency from start to finish. Each piece of equipment, from the rinsing unit to the capping machine, plays an essential role in the production process. By investing in advanced, automated systems, beverage manufacturers can reduce labor costs, minimize waste, and maintain competitive efficiency in a demanding market.

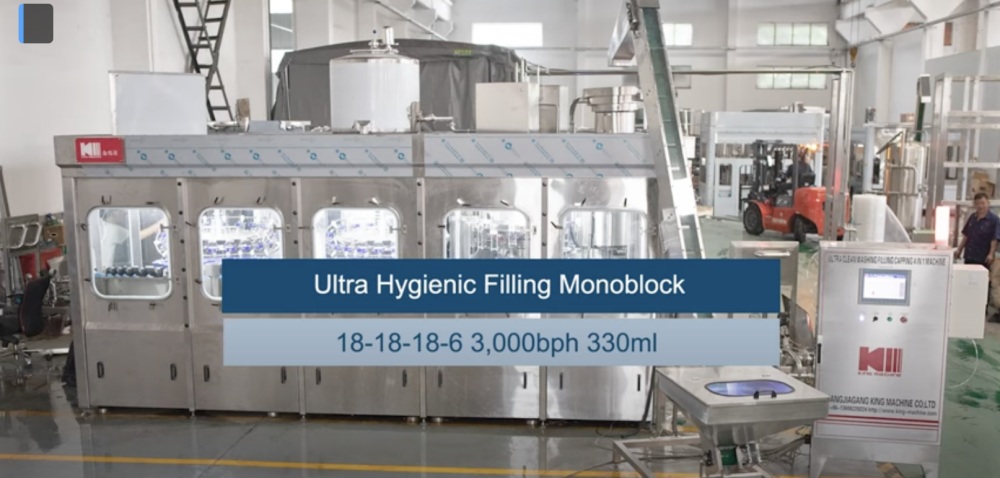

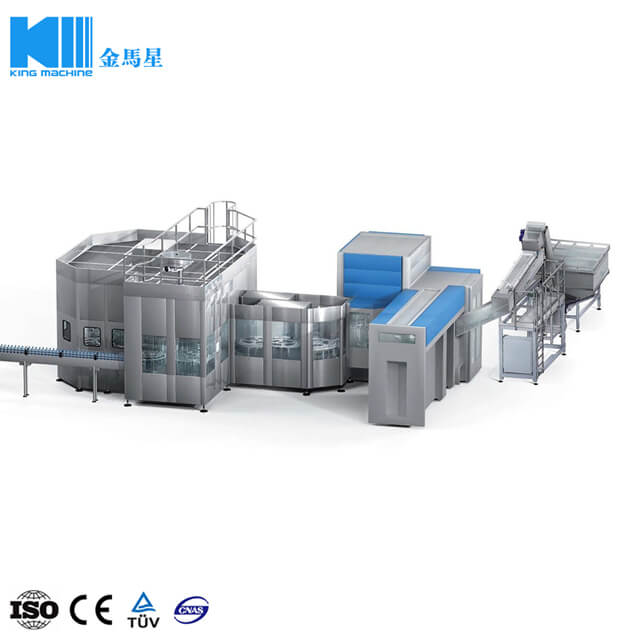

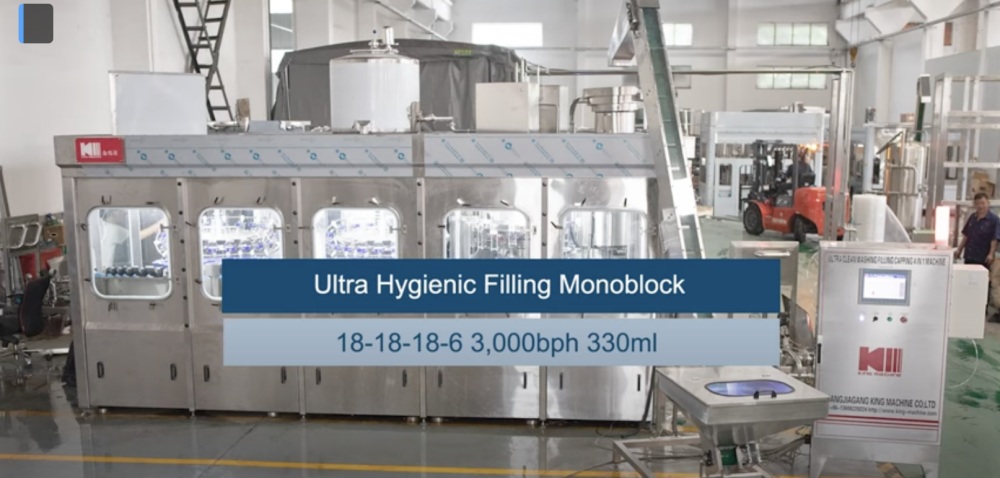

About King Machine

For businesses looking to build or upgrade a juice filling line, King Machine offers complete, intelligent production solutions. With years of experience in the PET plastic packaging industry, King Machine integrates preform feeding, blowing, labeling, filling, and capping into one seamless system.

Our Beverage Filling Machines, Juice Filling Lines, and Blowing-Filling-Capping Systems deliver exceptional efficiency and quality through advanced automation and engineering excellence. Backed by continuous innovation and professional expertise, King Machine helps beverage producers achieve optimized production, consistent performance, and long-term success.