In today’s competitive beverage industry, water filling machine plays a vital role in ensuring efficiency, hygiene, and product consistency. Whether you’re running a startup bottling line or scaling a large beverage plant, choosing the right water filling machine can significantly impact your production quality and operating costs.

In this article, we’ll explore the main types of water filling machines, their working principles, advantages, and how to choose the one that best fits your business needs.

1. What Is a Water Filling Machine?

A water filling machine is industrial equipment designed to automatically fill containers—typically bottles—with water or similar liquids. These machines are commonly used in bottled water plants, beverage factories, and packaging facilities that demand speed, hygiene, and accuracy.

Modern water filling machines can handle different bottle sizes and shapes, including PET, glass, and gallon containers. They also integrate processes such as rinsing, filling, and capping, all within one compact system to minimize manual labor and maximize throughput.

2. Why Choosing the Right Water Filling Machine Matters

Selecting the right type of water filling machine directly affects your:

Production efficiency — Faster machines can significantly boost output.

Operational costs — Automation reduces manpower and resource waste.

Product consistency — The right machine maintains accurate filling levels.

Hygiene and safety — Essential for bottled water and food-grade products.

Flexibility — Accommodates different bottle types and liquid viscosities.

For businesses in the bottled water, juice, or beverage industries, investing in the correct filling technology can enhance long-term competitiveness and return on investment.

3. Main Types of Water Filling Machines

Water filling machines can be categorized by automation level, bottle type, or filling method. Below are the most common types used across industries.

(1) Automatic Water Filling Machine

An automatic water filling machine performs rinsing, filling, and capping automatically without human intervention. It’s ideal for medium to large-scale water production plants that require continuous, high-speed output.

Key features:

Fully automated operation

High precision filling control

Suitable for PET and glass bottles

Supports bottle sizes from 200ml to 2L

Advantages:

Reduces labor cost

Improves hygiene by minimizing human contact

Stable and consistent performance

Applications: Bottled mineral water, purified water, and flavored water production lines.

(2) Semi-Automatic Water Filling Machine

Semi-automatic machines require manual loading and unloading of bottles. They are cost-effective for small-scale producers or businesses just starting in the bottled water industry.

Key features:

Manual bottle placement

Compact and affordable

Easy to maintain

Advantages:

Lower initial investment

Simple operation

Suitable for customized production batches

Applications: Small workshops, pilot projects, and low-volume bottling operations.

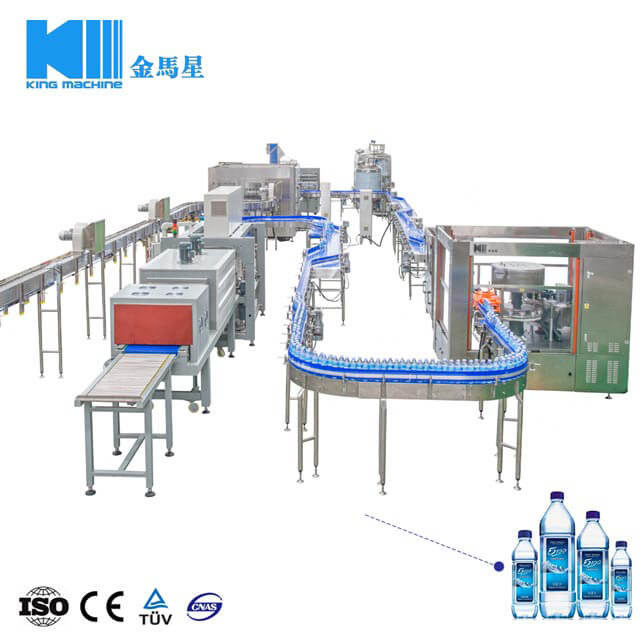

This integrated system combines three core processes — rinsing, filling, and capping — into a single compact unit. It’s designed for high-speed bottling lines that value space efficiency and automation.

Key features:

Three-in-one modular design

High-speed filling with precision valves

Compatible with PET and glass bottles

Advantages:

Saves floor space

Easy to clean and maintain

Reduces cross-contamination risk

Applications: High-capacity bottled water production lines and beverage factories.

For large containers, such as those used in office or home water dispensers, the 3–5 gallon filling machine is the perfect solution. It’s engineered to clean, fill, and seal large-capacity bottles efficiently.

Key features:

Handles bottles from 3 to 5 gallons

Includes multi-stage bottle washing system

High-level sanitation control

Advantages:

Reduces contamination risks

Ensures secure sealing

Suitable for returnable and reusable containers

Applications: Bulk water supply companies and commercial water delivery services.

The Blowing-Filling-Capping (BFC) system integrates preform blowing, bottle filling, and cap sealing into one continuous process. This eliminates the need to transfer bottles between separate machines, enhancing efficiency and cleanliness.

Key features:

One integrated system for the full process

Intelligent automation control

Compact footprint

Advantages:

Reduces material handling

Saves energy and space

Minimizes contamination and bottle damage

Applications: Premium bottled water production and high-end beverage manufacturing.

(6) Gravity and Pressure Filling Machines

Water filling machines can also be classified by filling method:

Gravity Filling Machine: Uses gravity to fill bottles with low-viscosity liquids like water. Cost-effective and suitable for still water production.

Pressure Filling Machine: Utilizes air pressure for carbonated beverages, ensuring consistent fill levels without foaming.

Applications: Gravity filling for water, pressure filling for carbonated drinks.

4. How to Choose the Right Water Filling Machine

Choosing the best water filling machine depends on several factors unique to your business:

Production Capacity:

Estimate the number of bottles you need to produce per hour or per day. High-speed automated lines suit large-scale operations, while semi-automatic machines suffice for small businesses.

Bottle Type and Size:

Select equipment compatible with your container materials (PET, glass, or gallons) and sizes (from 200ml to 20L).

Automation Level:

Fully automatic systems are ideal for high-output production, while semi-automatic options are better for startups and customized runs.

Budget and ROI:

Balance upfront investment with expected efficiency gains and labor savings. The most cost-effective choice is one that supports long-term scalability.

Maintenance and Support:

Choose a manufacturer that offers technical support, spare parts, and training. Reliable after-sales service ensures continuous operation and reduced downtime.

5. Why Work with King Machine

With decades of industry experience, King Machine has become a trusted global supplier in the PET plastic packaging and bottled beverage machinery industry.

We specialize in integrated filling solutions that cover the entire production process — from preform feeding, bottle blowing, labelling, and filling, to cap feeding. Our intelligent equipment systems enable continuous optimization and superior performance across diverse beverage lines.

Our core product range includes:

Water Filling Machine

Juice Filling Machine

Carbonated Soft Drink Filling Machine

3–5 Gallon Filling Machine

Beer Filling Machine

Wine Filling Machine

Blowing-Filling-Capping Machine

Oil and Daily Chemical Filling Machines

Water Treatment Plants

By leveraging advanced technology and deep expertise, King Machine helps clients achieve greater productivity, consistent quality, and lower production costs — all within a streamlined, high-performance system.

Conclusion

Selecting the right water filling machine is not just about equipment — it’s about efficiency, reliability, and scalability for your business. Understanding your production requirements, automation needs, and future growth plans will guide you to the perfect solution.

Whether you’re setting up a small bottled water line or upgrading a high-volume beverage plant, partnering with a trusted manufacturer like King Machine ensures you get the best combination of technology, durability, and service.

At King Machine, we deliver more than just machines — we deliver complete filling solutions that empower your business to thrive in a competitive market.