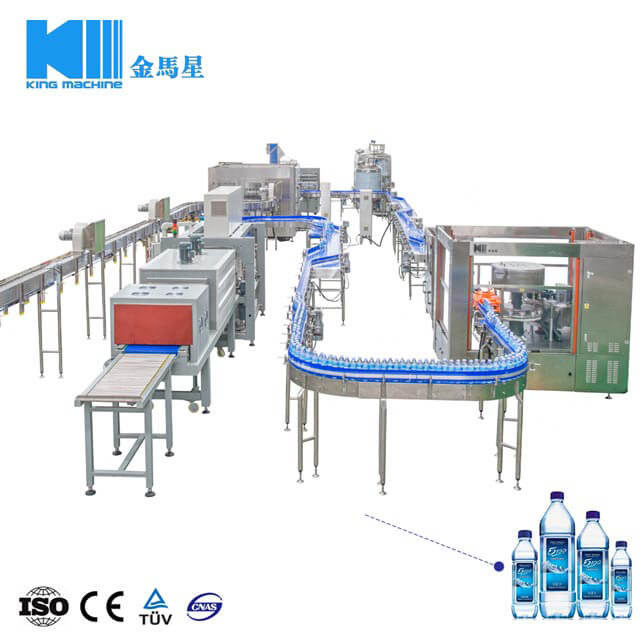

The machine is mainly applied for the filling of beverage. Integrating with washing, filling and sealing, it realizes full automation in the whole process, suitable for polyester bottle and plastic bottle filling of mineral water and purified water. The bottle types applicable for various parts are easily, conveniently and rapidly adjustable. It adopts new micro-negative pressure filling, stable and reliable. Compared with the machines of the same specification, the benefit of this machine is larger.

The machine adopts advanced OMRON programmable logic controller (PLC) to control the automatic running of the machine. The input bottle adopts air conveying device; the output bottle adopts adjustable speed way, which combines with the transducer of the host machine making the output bottle running more stable and reliable. The photoelectrical inspection of the running condition of various parts makes a higher automation and convenient operation. It is the ideal first-choice equipment of beverage manufacturers.

| Washing Workstation | 24 |

| Filling Workstation | 24 |

| Capping Workstation | 8 |

| Production Capacity | 12000B/H (500ml) |

| Machine Power | 4kw |

| Machine Weight | 7000Kg |

| External Dimensions(L*W*H) | 2800(mm)*2050(mm)*2200(mm) |

Automatic Mineral Water Bottling Plant Cost

Washing heads. *All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

*304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

*304/316 stainless steel washing pump |

|  Filling heads *304/316 Stainless steel high precision filling nozzle

*Filling volume adjustable in fine rank, same liquid level after filling

*All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

*304/316 stainless steel filling pump |

|  Capping heads *Place and capping system,

electromagnetic capping heads, with burden discharge function, make sure

minimum bottle crash during capping

*All 304/316 stainless steel construction

*No bottle no capping

* Automatic stop when lack of bottle. |

Main Features.

1.

Using the wind sent access and move wheel in the bottle directly

connected technology; canceled screw and conveyor chains, this enable

the change the bottle-shaped become easier.

2. Bottles

transmission adopt clip bottleneck technology, bottle-shaped transform

not need to adjust the equipment level, only change related the curved

plate, wheel and nylon parts is enough..

3. The specially

designed stainless steel bottle washing machine clip is solid and

durable, no touch with the screw location of bottle mouth to avoid

secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6.

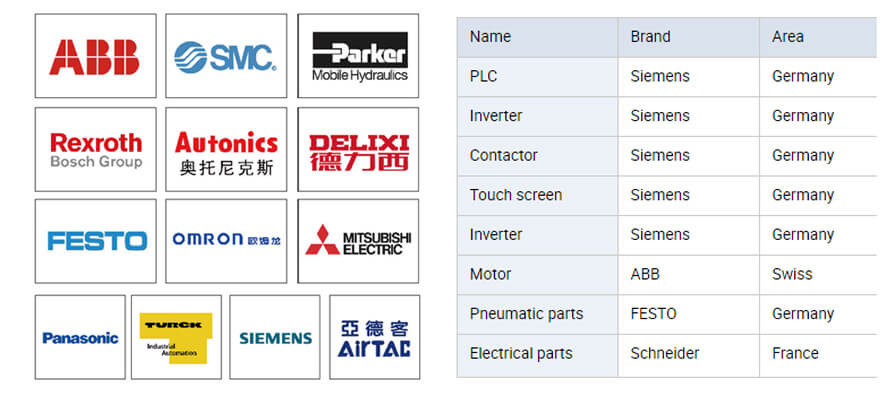

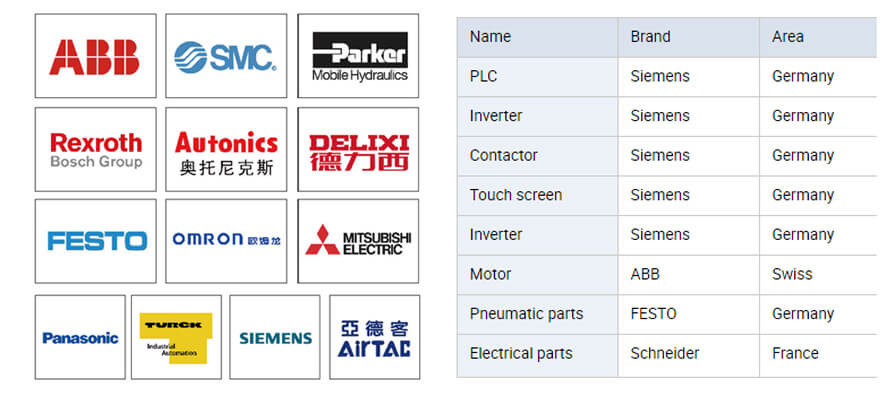

Host adopt advanced PLC automatic control technology, the key

electrical components from famous company such as Japan's Mitsubishi,

France Schneider, OMRON.

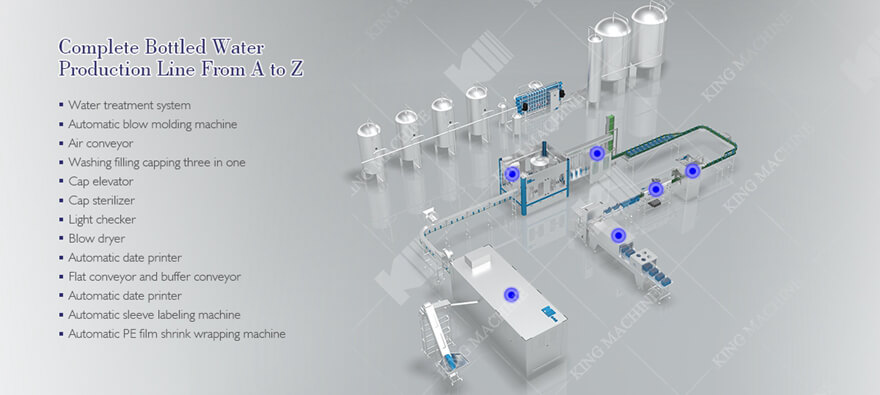

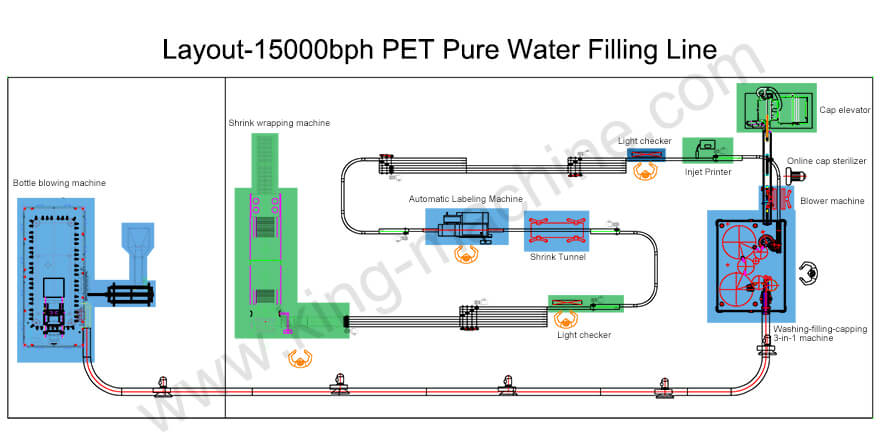

Flow chart: (Pure water filling machine):

A)Bottle production line PET Resin --Injection moulding machine -Botlte blowing machine --PET bottle

B)Water treatment system Raw

water--Pump--Silica sand filter--Carbon filter--Water softner--Reverse

Osmosis -UV sterilizer-Ozone generator--Finished water tank

C)Filling&Packing part Bottle

unscrambler--Air conveyor--Washing,filling,capping 3in1 machine--Light

checker--Blow dryer--Dater printer--Lableing machine --Packing machine

-Stock